Tuesday, May 28, 2019

Home automation is significantly changing homeowners’ expectations and home builders are responding accordingly by offering homes that are smart and increasingly all-electric. Bob Torbin, director of codes and standards with OmegaFlex (Exton, Pa.), believes this is why NOW is a call-to-action time for the propane industry.

“The gas industry could become a minor energy player, if not obsolete. I’m not saying home automation is going to kill LPG, but it’s going to be one of the contributing factors to a decline in sales,” Torbin said.

“The gas industry could become a minor energy player, if not obsolete. I’m not saying home automation is going to kill LPG, but it’s going to be one of the contributing factors to a decline in sales,” Torbin said.

One solution, according to Torbin, is for the propane industry to offer home-automation-ready piping infrastructure and provide the features now. “The home automation world is blossoming around us, but no one thinks of propane and home automation. Manufacturers [of LPG appliances] are only thinking of making appliances safer and more reliable. Why not think ‘Alexa, turn on my gas grill’? ‘Alexa, cook my steak medium and call me when it’s ready’?”

Although the LPG appliance manufacturers are not yet offering smart gas appliances, Torbin said the resources are available to give new and existing houses the capability of being “smart-ready” and to have the infrastructure for the LPG appliances of the future added to existing houses at any time.

He addressed the benefits and logistics of preparing the LPG home for automation and the associated load growth during his presentation of “Low Cost Residential Load Growth Strategies” at the 2019 NPGA Southeastern Convention & International Propane Expo.

The propane industry can increase gas load per customer using semirigid metallic tubing operated at elevated pressure to create a multifunctional gas distribution network in homes. Gas lines can be routed cost-effectively to every portion of the home (including outdoors) during both construction and remodeling including pre-piping of key battleground areas, such as kitchens and laundries. Gas convenience outlets will permit gas appliances to be “plugged in” just like their electric equivalents.

The propane industry can increase gas load per customer using semirigid metallic tubing operated at elevated pressure to create a multifunctional gas distribution network in homes. Gas lines can be routed cost-effectively to every portion of the home (including outdoors) during both construction and remodeling including pre-piping of key battleground areas, such as kitchens and laundries. Gas convenience outlets will permit gas appliances to be “plugged in” just like their electric equivalents.

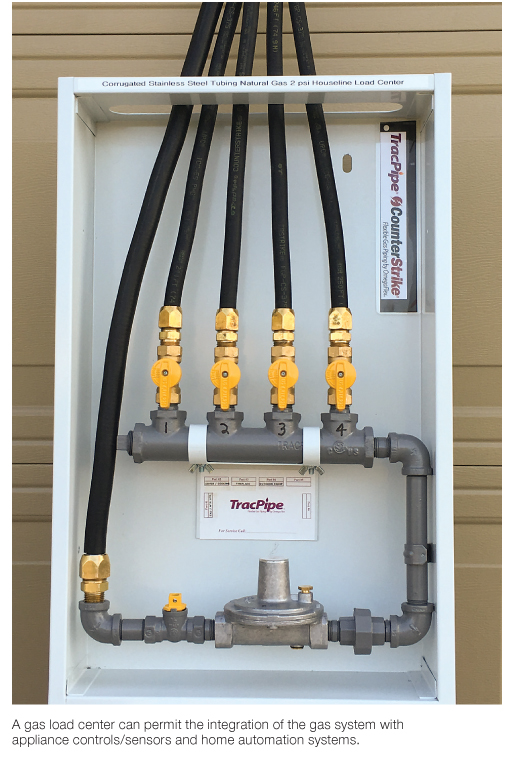

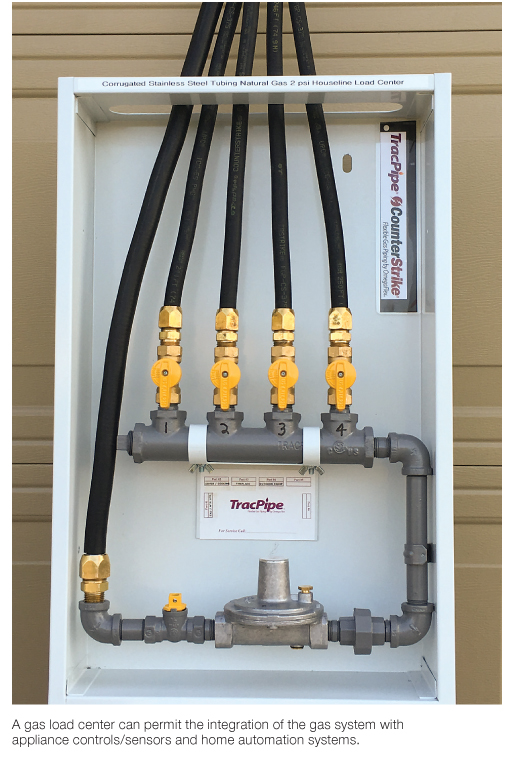

Use of elevated pressure reduces initial cost while providing future load growth, Torbin said. A gas load center will permit the integration of the gas system with appliance controls/sensors and home automation systems. Automatic shut-off valves can be triggered to operate based on methane sensors, high CO levels, and smoke and fire alarms, as well as be integrated into other home security and life-safety systems.

DESIGNING THE INFRASTRUCTURE

“My presentation is meant to inspire members of the LPG industry to get on board before they get left behind. You don’t need an IT department,” he said. “When we think about new gas loads, such as power generators, tankless water heaters, gas logs—how do you accommodate for this load growth in a cost-effective way without having to replumb the entire house when remodeling?”

Designing the infrastructure for LPG appliances in advance provides several benefits. It allows you to anticipate future usage so you can add gas appliances in the future when home automation catches up. It also allows you to be prepared for changes in consumer demand and awareness. Future load growth starts with building strategies into the infrastructure from the very start.

“No one is doing this now. It’s not like a package you can buy at Home Depot, but the technology and know-how are already here,” Torbin explained.

“This talk is meant to ignite fresh thinking and strategy to at least stay up with the market curve on home automation. We’re not making smart gas appliances, but we can make smart gas piping systems.”

“We’re not doing enough to keep up with what’s going on in the electrical community. We [the propane industry] are not even in on the ground floor. We’re just trying to survive. We have to think beyond survival. We need to give people a better reason to have propane than just cost advantages.”

“The writing is on the wall. Your electrical competitors are already planning for our demise,” Torbin said. “This presentation is a wake-up call.”

“The writing is on the wall. Your electrical competitors are already planning for our demise,” Torbin said. “This presentation is a wake-up call.”

California, for example, is soon to be the first state to mandate solar-energy installations for every new single-family home as well as multifamily residential buildings up to three stories, including condos and apartment complexes. Many new subdivisions are already building only all-electric houses.

A CALL TO ACTION

There are challenges, Torbin admitted, to smart gas homes becoming reality:

Bob Torbin has spent more than 25 years pursuing a career-long effort in support of innovative piping systems and technologies. He has been involved with innovative, lightning-resistant corrugated stainless steel tubing (CSST) technologies, including revisions to all appropriate model codes, updating of product standards, coordinating various company and industry research projects, and advocating for state and local code acceptance. His work has included participation on many industry committees and organizations promoting the safe use of fuel gas products including installation practices and installer training. — Karen Massman VanAsdale

“The gas industry could become a minor energy player, if not obsolete. I’m not saying home automation is going to kill LPG, but it’s going to be one of the contributing factors to a decline in sales,” Torbin said.

“The gas industry could become a minor energy player, if not obsolete. I’m not saying home automation is going to kill LPG, but it’s going to be one of the contributing factors to a decline in sales,” Torbin said.One solution, according to Torbin, is for the propane industry to offer home-automation-ready piping infrastructure and provide the features now. “The home automation world is blossoming around us, but no one thinks of propane and home automation. Manufacturers [of LPG appliances] are only thinking of making appliances safer and more reliable. Why not think ‘Alexa, turn on my gas grill’? ‘Alexa, cook my steak medium and call me when it’s ready’?”

Although the LPG appliance manufacturers are not yet offering smart gas appliances, Torbin said the resources are available to give new and existing houses the capability of being “smart-ready” and to have the infrastructure for the LPG appliances of the future added to existing houses at any time.

He addressed the benefits and logistics of preparing the LPG home for automation and the associated load growth during his presentation of “Low Cost Residential Load Growth Strategies” at the 2019 NPGA Southeastern Convention & International Propane Expo.

The propane industry can increase gas load per customer using semirigid metallic tubing operated at elevated pressure to create a multifunctional gas distribution network in homes. Gas lines can be routed cost-effectively to every portion of the home (including outdoors) during both construction and remodeling including pre-piping of key battleground areas, such as kitchens and laundries. Gas convenience outlets will permit gas appliances to be “plugged in” just like their electric equivalents.

The propane industry can increase gas load per customer using semirigid metallic tubing operated at elevated pressure to create a multifunctional gas distribution network in homes. Gas lines can be routed cost-effectively to every portion of the home (including outdoors) during both construction and remodeling including pre-piping of key battleground areas, such as kitchens and laundries. Gas convenience outlets will permit gas appliances to be “plugged in” just like their electric equivalents.Use of elevated pressure reduces initial cost while providing future load growth, Torbin said. A gas load center will permit the integration of the gas system with appliance controls/sensors and home automation systems. Automatic shut-off valves can be triggered to operate based on methane sensors, high CO levels, and smoke and fire alarms, as well as be integrated into other home security and life-safety systems.

DESIGNING THE INFRASTRUCTURE

“My presentation is meant to inspire members of the LPG industry to get on board before they get left behind. You don’t need an IT department,” he said. “When we think about new gas loads, such as power generators, tankless water heaters, gas logs—how do you accommodate for this load growth in a cost-effective way without having to replumb the entire house when remodeling?”

Designing the infrastructure for LPG appliances in advance provides several benefits. It allows you to anticipate future usage so you can add gas appliances in the future when home automation catches up. It also allows you to be prepared for changes in consumer demand and awareness. Future load growth starts with building strategies into the infrastructure from the very start.

“No one is doing this now. It’s not like a package you can buy at Home Depot, but the technology and know-how are already here,” Torbin explained.

“This talk is meant to ignite fresh thinking and strategy to at least stay up with the market curve on home automation. We’re not making smart gas appliances, but we can make smart gas piping systems.”

“We’re not doing enough to keep up with what’s going on in the electrical community. We [the propane industry] are not even in on the ground floor. We’re just trying to survive. We have to think beyond survival. We need to give people a better reason to have propane than just cost advantages.”

“The writing is on the wall. Your electrical competitors are already planning for our demise,” Torbin said. “This presentation is a wake-up call.”

“The writing is on the wall. Your electrical competitors are already planning for our demise,” Torbin said. “This presentation is a wake-up call.”California, for example, is soon to be the first state to mandate solar-energy installations for every new single-family home as well as multifamily residential buildings up to three stories, including condos and apartment complexes. Many new subdivisions are already building only all-electric houses.

A CALL TO ACTION

There are challenges, Torbin admitted, to smart gas homes becoming reality:

- The propane industry is not prepared to address the problem. Nothing is going on in research and development to help LPG suppliers offer smart products; and

- Manufacturers are not incentivized to make smart gas products. “They keep selling the same things year after year,” Torbin said. “Why isn’t my furnace telling me when the air filter needs to be replaced or maintaining optimum air-fuel mixture?”

Bob Torbin has spent more than 25 years pursuing a career-long effort in support of innovative piping systems and technologies. He has been involved with innovative, lightning-resistant corrugated stainless steel tubing (CSST) technologies, including revisions to all appropriate model codes, updating of product standards, coordinating various company and industry research projects, and advocating for state and local code acceptance. His work has included participation on many industry committees and organizations promoting the safe use of fuel gas products including installation practices and installer training. — Karen Massman VanAsdale