Thursday, March 21, 2019

VanderYacht Propane (Lynden, Wash.) needed a specialized truck, but needed it only occasionally. To make sure the truck wouldn’t sit idle too long, the company decided to set it up so it could serve more than one purpose. What they developed was a truck that could be fitted with interchangeable bodies—a truck that could be many trucks in one.

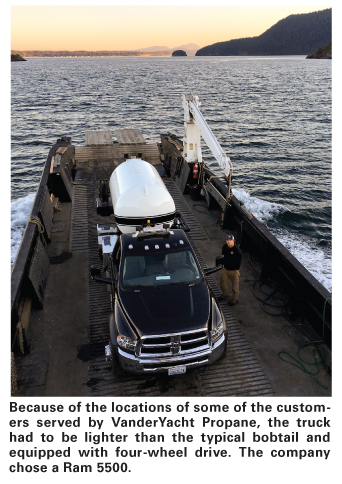

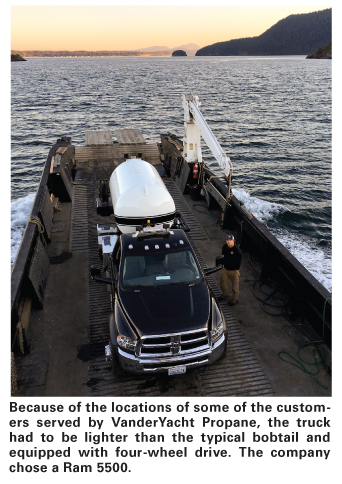

The challenge that inspired this project was the company’s location. To serve customers in western Washington, VanderYacht Propane must occasionally send a truck up into mountains or over a suspension bridge. These treks require a vehicle that is lighter than the typical bobtail and equipped with four-wheel drive, so VanderYacht Propane chose a Ram 5500.

They then set out to make sure the truck could serve more than one purpose. Working with Fort Fabrication (Surrey, B.C.), they designed three “modulars”—interchangeable truck bodies that could be quickly rolled on and rolled off the Ram chassis. With the installation of one of these modulars, VanderYacht Propane’s truck can serve as a bobtail, a service truck, or a dump truck.

“We already had a smaller four-wheel-drive truck that sits nine months a year,” Bryan VanderYacht, president and owner of VanderYacht Propane, told BPN. “We decided, if we’re going to do another truck, why not do one that can do three jobs? Our new truck does three jobs and it probably can do more when we think of them.”

What makes these conversions possible is a hooklift system like those that are used to pick up and drop off recycling bins at construction sites. VanderYacht credits his friends at Lauts Inc., a family-owned recycling company in Mount Vernon, Wash., with showing him the hooklifts they use and recommending Fort Fabrication to install the system and build the truck beds. The system used on VanderYacht Propane’s truck is manufactured by Ampliroll. It features a hydraulic hooklift system that pulls a container or a truck body onto the chassis and then holds it securely in place. Several Ampliroll-branded roll-on truck bodies are available, but VanderYacht Propane had its own custom modulars built.

With the exception of the tank on the bobtail bed, the three beds for VanderYacht Propane’s truck were made by Fort Fabrication. The company also installed the Ampliroll AL 90L 13,000-lb hooklift. The hooklift system not only rolls a bed on and off the chassis, but also holds the bed in place while in use; the hooklift comes with body locks.

Brad Astbury, president of Fort Fabrication, told BPN this is the first time the company has built a bed that was to be fitted with a propane tank. (The installation of the tank and accessories was done by Ransome Mfg.) Fort Fabrication manufactures truck bodies that are utilized by many industries.

“We supply truck bodies to municipalities and all types of companies,” he said. “Roll-on/roll-off bodies are becoming very common in most industries that use vocational trucks. I relate it to agricultural machines—you don’t change machines to do different jobs, you change attachments.”

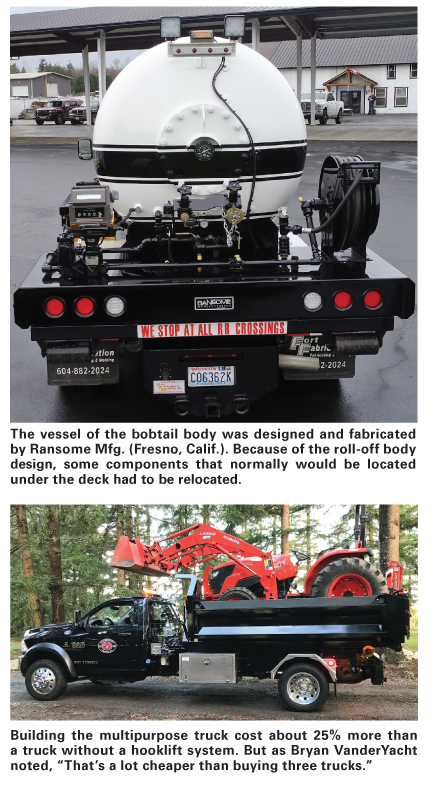

The vessel of the bobtail body was designed and fabricated by Ransome Mfg. (Fresno, Calif.). Here, for VanderYacht Propane’s multipurpose truck, there was a need to relocate components that normally would be located under the deck. “Because of the nature of this being a roll-off body deck, we could have no appurtenances below deck level,” Arch Hudelson, special projects director, western region, at Ransome Mfg., told BPN.

Starting out with one of the beds made by Fort Fabrication, the team at Ransome added the tank body and accoutrements. Equipment that would normally be below the deck was designed to come out the side of the tank, laterally, behind the cab on the driver’s side.

Ransome also built hookups for the Ram power take-off (PTO) unit. The propane deck requires different equipment than the crane of the service truck deck, so these hookups were designed to be easy to swap out. “It takes just a few minutes once you are well-versed in swapping it out,” Hudelson said. “It’s like putting a boat on a trailer.”

“The truck worked out very, very well,” he added. “It has accessibility, because of the four-wheel-drive chassis, and it gets double-duty out of the cab and chassis. This concept has validated itself; it has performed as envisioned. Other propane marketers are looking at having a replica fabricated.”

VanderYacht Propane’s truck and three modulars have been in use for six months. The person who has used the truck the most has been Denver VanderYacht, service technician, delivery driver, and sales and marketing manager at VanderYacht Propane. He says the switch from one modular to another can be done in 10 minutes or less. It requires setting down one body and picking up another, just as hooklift trucks do with containers at construction sites. The driver does this from inside the cab. For the service truck and bobtail modulars, there are also hydraulic hoses and valves and electrical connectors to be attached. “Once you get the hang of it, it’s like riding a bike,” Denver VanderYacht told BPN. “It’s easy; it doesn’t take a lot of time or intensity.”

During the time he’s been driving the truck, it’s already served its different purposes. During the summer, the truck served primarily as a service truck. Now that it’s winter, it is serving as a bobtail. “We’ve used it a lot,” he said. “What we need it for is seasonal, and we can change it whenever we want.”

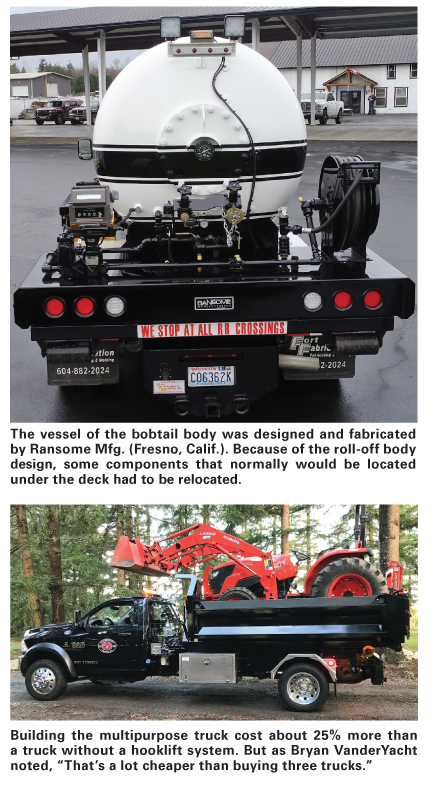

Building the multipurpose truck cost about 25% more than a truck without a hooklift system. But as Bryan VanderYacht noted, “That’s a lot cheaper than buying three trucks.” —Steve Relyea

The challenge that inspired this project was the company’s location. To serve customers in western Washington, VanderYacht Propane must occasionally send a truck up into mountains or over a suspension bridge. These treks require a vehicle that is lighter than the typical bobtail and equipped with four-wheel drive, so VanderYacht Propane chose a Ram 5500.

They then set out to make sure the truck could serve more than one purpose. Working with Fort Fabrication (Surrey, B.C.), they designed three “modulars”—interchangeable truck bodies that could be quickly rolled on and rolled off the Ram chassis. With the installation of one of these modulars, VanderYacht Propane’s truck can serve as a bobtail, a service truck, or a dump truck.

“We already had a smaller four-wheel-drive truck that sits nine months a year,” Bryan VanderYacht, president and owner of VanderYacht Propane, told BPN. “We decided, if we’re going to do another truck, why not do one that can do three jobs? Our new truck does three jobs and it probably can do more when we think of them.”

What makes these conversions possible is a hooklift system like those that are used to pick up and drop off recycling bins at construction sites. VanderYacht credits his friends at Lauts Inc., a family-owned recycling company in Mount Vernon, Wash., with showing him the hooklifts they use and recommending Fort Fabrication to install the system and build the truck beds. The system used on VanderYacht Propane’s truck is manufactured by Ampliroll. It features a hydraulic hooklift system that pulls a container or a truck body onto the chassis and then holds it securely in place. Several Ampliroll-branded roll-on truck bodies are available, but VanderYacht Propane had its own custom modulars built.

With the exception of the tank on the bobtail bed, the three beds for VanderYacht Propane’s truck were made by Fort Fabrication. The company also installed the Ampliroll AL 90L 13,000-lb hooklift. The hooklift system not only rolls a bed on and off the chassis, but also holds the bed in place while in use; the hooklift comes with body locks.

Brad Astbury, president of Fort Fabrication, told BPN this is the first time the company has built a bed that was to be fitted with a propane tank. (The installation of the tank and accessories was done by Ransome Mfg.) Fort Fabrication manufactures truck bodies that are utilized by many industries.

“We supply truck bodies to municipalities and all types of companies,” he said. “Roll-on/roll-off bodies are becoming very common in most industries that use vocational trucks. I relate it to agricultural machines—you don’t change machines to do different jobs, you change attachments.”

The vessel of the bobtail body was designed and fabricated by Ransome Mfg. (Fresno, Calif.). Here, for VanderYacht Propane’s multipurpose truck, there was a need to relocate components that normally would be located under the deck. “Because of the nature of this being a roll-off body deck, we could have no appurtenances below deck level,” Arch Hudelson, special projects director, western region, at Ransome Mfg., told BPN.

Starting out with one of the beds made by Fort Fabrication, the team at Ransome added the tank body and accoutrements. Equipment that would normally be below the deck was designed to come out the side of the tank, laterally, behind the cab on the driver’s side.

Ransome also built hookups for the Ram power take-off (PTO) unit. The propane deck requires different equipment than the crane of the service truck deck, so these hookups were designed to be easy to swap out. “It takes just a few minutes once you are well-versed in swapping it out,” Hudelson said. “It’s like putting a boat on a trailer.”

“The truck worked out very, very well,” he added. “It has accessibility, because of the four-wheel-drive chassis, and it gets double-duty out of the cab and chassis. This concept has validated itself; it has performed as envisioned. Other propane marketers are looking at having a replica fabricated.”

VanderYacht Propane’s truck and three modulars have been in use for six months. The person who has used the truck the most has been Denver VanderYacht, service technician, delivery driver, and sales and marketing manager at VanderYacht Propane. He says the switch from one modular to another can be done in 10 minutes or less. It requires setting down one body and picking up another, just as hooklift trucks do with containers at construction sites. The driver does this from inside the cab. For the service truck and bobtail modulars, there are also hydraulic hoses and valves and electrical connectors to be attached. “Once you get the hang of it, it’s like riding a bike,” Denver VanderYacht told BPN. “It’s easy; it doesn’t take a lot of time or intensity.”

During the time he’s been driving the truck, it’s already served its different purposes. During the summer, the truck served primarily as a service truck. Now that it’s winter, it is serving as a bobtail. “We’ve used it a lot,” he said. “What we need it for is seasonal, and we can change it whenever we want.”

Building the multipurpose truck cost about 25% more than a truck without a hooklift system. But as Bryan VanderYacht noted, “That’s a lot cheaper than buying three trucks.” —Steve Relyea