Editor’s Note: The following article from February 2024 states, “The size of the tank determines the allowed fill level during transport. A 1,000-gallon tank cannot be more than 5% full when transporting it. However, tanks that are 500 gallons or less can be transported at up to 80% fill levels.”

Theodore Lemoff of TLemoff Engineering submitted a clarification to the editor: “NFPA 58-2024 states: 9.6.2.2 Where a container is transported with more LP-Gas than 5 percent of its water capacity in a liquid form, all of the following conditions shall apply: (1) The container shall not be filled beyond the filling limit of Section 7.4. (2) Transportation shall be permitted only to move containers from a stationary or temporary installation to a bulk plant. (3) Valves and fittings shall be protected by a method approved by the authority having jurisdiction to minimize the possibility of damage. (4) Lifting lugs shall not be used to move these containers.

“As NFPA 58 is adopted by the states, it does not apply to or supersede federal regulations for the transportation of hazardous materials. Transportation of ASME containers of this size with more than 5% fill is not permitted by DOT. However an exception can be requested from the appropriate state agency to allow such transportation.”

Propane is used all over the world for a wide range of purposes. While used as a staple in people’s everyday lives, propane is a hazardous substance that needs to be respected and handled properly. Transporting and handling propane tanks requires adhering to established guidelines and rules to maximize safety.

The rules and regulations for transporting propane differ depending on which type of vehicle is being used. If transporting propane cylinders in enclosed vehicles, certain rules apply. Here, we will look at transporting propane tanks in open trailers or trucks.

Loading the Tank

Prior to loading a tank on a vehicle, the container must be inspected. Defects in the tank to look for include leaks, dents, weld defects, corroded areas or other conditions making the container unsafe. After completing a thorough inspection of the tank, a record of the inspection should be signed and dated by the person who performed the inspection.

When lifting the tank with a crane or propane tank trailer, it should be secured properly by slings or straps. Be sure the straps are suitable to the weight of the tank and are not frayed or otherwise compromised. Always use the lifting points on a tank, as they are designed to withstand the load and stress. If a tank has more than 5% fill, underbelly straps must be used instead of the lugs, and the strap has to go all the way around the tank.

Make sure the load is evenly distributed during the lift and avoid putting any pressure on valves or fittings on the tank. Lastly, always monitor the tank throughout the lift, watching to make sure it is balanced and secure.

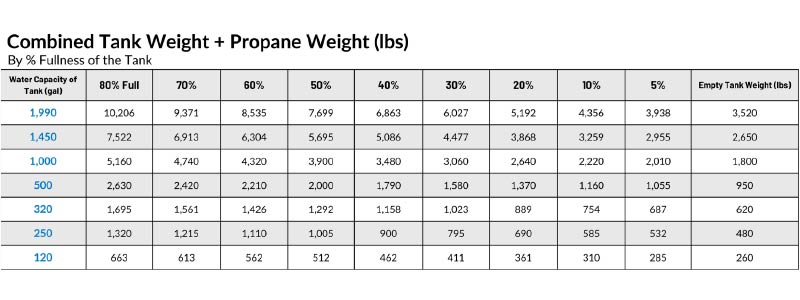

When transporting a tank or using a crane to lift it, it is important to understand the weight of the load. Check your equipment and make sure that it is suitable for the weight. This will prevent accidents and damage to equipment. Figure 1 is a chart that compiles the weights of different tank sizes plus the amount of propane they contain to give an overall weight. Use this chart as a helpful guide when transporting tanks.

Securing the Tank

Once on the bed of the truck, the tank needs to be secured so that it does not roll or slide. A 1,000-gallon tank requires the use of three tie-down straps, while a 500-gallon tank requires the use of at least two tie-down straps. Find the D-rings or other securing points and use high-quality straps to secure the tank to the bed. Make sure the tank is balanced and the weight evenly distributed to avoid movement during transport.

The use of blocks helps prevent the tank from shifting — many beds have padding or protection so they won’t scratch your tank. Any tank that has more than 5% fill has to be put on saddles on a truck and cannot sit on the legs of the tank. Also, the tank cannot sit outside the vehicle past the flagging distance.

Non-virgin tanks that are 1,000 gallons or greater are required to have placards on each side and both ends of the tank. Propane tanks that are 500 gallons or less need to be placarded on the left and right sides during transport.

The size of the tank determines the allowed fill level during transport. A 1,000-gallon tank cannot be more than 5% full when transporting it. However, tanks that are 500 gallons or less can be transported at up to 80% fill levels. [Please see editor's note above for updated clarification.]

Propane’s volume in a tank will increase in the liquid state when heated. A tank that is filled to a volume of 80% liquid propane gas at zero degrees Celsius will increase its volume to 100% full at an increased temperature of 64 C. This is because as the temperature rises, the pressure inside the tanks also increases. Therefore, a preventative measure is to never fill a propane tank to more than 80% its capacity to allow for fluctuations.

Propane’s volume in a tank will increase in the liquid state when heated. A tank that is filled to a volume of 80% liquid propane gas at zero degrees Celsius will increase its volume to 100% full at an increased temperature of 64 C. This is because as the temperature rises, the pressure inside the tanks also increases. Therefore, a preventative measure is to never fill a propane tank to more than 80% its capacity to allow for fluctuations.

It is important to know how to read the gauge on a propane tank. The numbers on the gauge represent how full the tank is as a percentage. When the needle is on 80, the tank is full of propane. When the needle is on 40, it is half full of propane.

When setting a tank, a few reminders will keep the service tech safe and efficient:

- Position the truck correctly the first time so you don’t have to move it.

- Know your distance and load. Use a tape measure to determine distances for setting the tank.

- Keep the load close to the ground in case of functional failure and make sure you are not underneath.

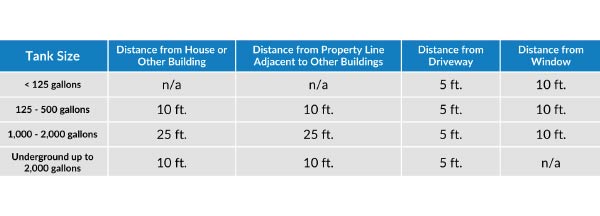

Figure 2 Keep at least an outreached distance away so you can steady the load but not be too close to it. The distance to buildings and other objects is important to measure when placing a tank. The size of the tank determines the distance the tank can be set from different objects. Use Figure 2 as a reference.

It is important to always follow the regulations on transporting propane gas to maximize safety for both the service technicians and consumers of propane. The Department of Transportation (DOT) has some general transport rules you should be aware of:

- Requalification: You should requalify propane cylinders every five to 10 years after their manufacture date.

- Capacity: The DOT states that you cannot fill cylinders to more than 80% capacity.

- Properly Secured: All propane tanks need to be secured properly during transport.

- Ventilation: Adequate ventilation is required in transporting propane cylinders or tanks. Propane gas is a clean and environmentally friendly fuel. However, it can be dangerous. If liquid propane gas comes into contact with skin, it can cause frostbite and damage. A dented tank could leak, which could result in fire. If a tank is overfilled, it can explode or become unsafe to use. A sign of this is an overwhelming smell of gas or the additive that gives odorless propane a scent.

It is important as a propane marketer to understand the risks in transporting propane tanks and to follow the rules and regulations set up by local, state and federal agencies. With precautions taken, propane gas will continue to provide people with a clean and versatile fuel for heating homes, using appliances, transportation and more.