Tuesday, July 23, 2019

Years ago, when William (Bill) Young was asked by a manager why he was resigning a job, he answered, “I no longer whistled while driving to work in the morning.” That has been a theme throughout his long career in the propane industry and even in his college days: he has dedicated his time to conquering challenging projects and having fun while doing it.

Young’s career in the propane industry started with a summer job painting cylinders while in college. A week after being hired, and after answering “yes” when asked if he could do mechanical work, he completed his first propane conversion on a lift truck. As the end of summer neared, his employer asked if he would consider staying on and going to night school.

Young’s career in the propane industry started with a summer job painting cylinders while in college. A week after being hired, and after answering “yes” when asked if he could do mechanical work, he completed his first propane conversion on a lift truck. As the end of summer neared, his employer asked if he would consider staying on and going to night school.

A Key Player

He did. More than half a century later, after working in several positions in the industry, Young is vice president of engineering for Superior Energy Systems (Columbia Station, Ohio). Over the years, he has served as a key player in the sale, design, engineering, construction, manufacture, and service of propane gas equipment.

His studies in college were varied, too. “I had an unusual approach to college,” Young recently told BPN. “I studied whatever interested me.” Between 1959 and 1965, at Youngstown University and the University of Pittsburgh, that included the basic sciences, mathematics, creative writing, philosophy, and music. Later he took a host of engineering courses. “As a consequence, I have 148 hours between Youngstown and Pitt,” he says. (Generally, 120 hours is enough for a bachelor’s degree.) “However, none of those things resulted in a degree. My wife once suggested I had become a professional student.”

Long, Varied Career

After accepting the offer to stay on at the propane company, Young’s long and varied career really got underway. The company he started with was Industrial Gases, a small independent propane company in Pittsburgh. The man who assigned him that first propane conversion and later asked him to stay on was the company’s president, Jerry Apt. Young became staff engineer in 1961.

“Industrial Gases had no domestic customers; we supplied industry only,” Young says. “As a small company, we shared duties as required. We drove trucks, filled cylinders, did service work, made sales calls, developed advertising, and designed systems. It was a wonderful place to work.”

While at Industrial Gases, Young and others performed hundreds of forklift truck conversions. They also converted several fleets of trucks to operate on propane fuel. All their personal vehicles ran on propane too. Young purchased his first new car—a 1962 Oldsmobile 88—and within two weeks it was running on propane. “I had propane vehicles continuously until 1983, when my wife asked if our next car could have a usable trunk.”

Many Interesting Things

At Industrial Gases, Young and others tried many interesting things. They worked with U.S. Steel to develop heated railroad cars to deliver hot tar to customers. They worked with oil well drillers to provide propane/air mixtures at 250% UFL (upper flammability limit) to allow drilling into gas-bearing sands in certain counties in Pennsylvania. They purchased a small fleet of old twin-barrel trailers and then delivered propane fuel to oil well rigs by simply exchanging trailers.

In 1965, Industrial Gases was acquired by Ugite, a propane subsidiary of UGI Corp. Young managed a district and then became sales manager of Ohio. He was also a representative of APCO (Applied Engineering Co.), a major manufacturer of propane vaporizers and propane/air mixers for standby fuel. Ugite transitioned to AmeriGas, and Young became manager of specialty sales and engineering (sales and construction of standby fuel systems for the U.S.).

In 1977, Young resigned from AmeriGas and became vice president of sales and engineering for Alternate Engine Systems, a manufacturer of propane vaporizers and propane/air blenders and mixers.

“I missed the closeness of smaller companies,” he explains. The operations manager offered a raise and then a company car. When Young still said no, the manager asked why he was leaving. That’s when he answered that he no longer whistled on his way to work. “There was a pause, then he said, ‘That’s the best reason I ever heard for resigning a job.’”

A Fun Time

Joining Alternate Energy Systems was like returning to Industrial Gases. “The people were delightful, and everyone pushed to make it successful,” Young explains. “[Owner John Hallberg] had great vision and was outstanding at developing concepts. I was good at taking concepts and developing usable products. It was a fun time.”

While there, Young developed many automatic controls for systems, which allowed self-adjustment to maintain fuel quality. He and Hallberg worked on Hallberg’s POM (piston operated mixer) mixing valve. “It is so simple, yet accurate,” Young says. Young also designed and sold an ethane vaporizer to a steel company that was hoping to have available quantities of liquid ethane for fuel. “We were in the early stages of the energy crisis, and sales were good,” he explains. They also started an affiliate construction company, Alternate Energy Installations in Ohio. In 1983, Young became company president.

In 1989, Young left Alternate Energy Systems and worked at a nearby design/build contractor that specialized in propane systems. Over the next decade, he and the company designed and installed many natural gas utility peak shaving plants.

“All It Took Was Dedication”

“All It Took Was Dedication”

In 2002, Young and a small group started Superior Energy Systems and procured the assets of his previous employer. “We had the personnel, we had the contacts, and we had the knowledge to succeed,” he says. “All it took was dedication.” Today, Superior Energy Systems is one of the leading engineering, procurement, and construction contractors for natural gas liquids.

After being contracted to supply and install a number of auto fuel dispenser packages, and seeing they seemed relatively simple to build, Superior Energy Systems started manufacturing dispensers. Today, the company manufactures a wide range of propane autogas dispensing systems.

“Alliance AutoGas opened up a much larger market for us for dispensers,” Young says. “It was easier to have Alliance handle distributing the information on our behalf. The driving force behind propane autogas was my partner Donald Fernald. He has an astute view of future trends.”

Then and Now

Looking back at the previous 55-plus years, Young says there are two differences between then and now that really stand out.

One involves equipment design: “Over the years, there have been many changes in equipment design,” he says. “When I started, all of the control instruments were pneumatic. We went from pneumatic to digital and from digital to PLC (programmable logic computer). In earlier days, control instruments were grouped around each process. Now a central PC connects with a number of remote PLC systems, which allows remote monitoring and control if needed.”

The second change involves propane marketers: “Propane companies are far different now than when I first worked in the industry. Few propane companies have servicemen for appliance work. The only concern is to deliver gas. While I have no vast knowledge of the domestic business, I believe that marketers have lost most of the personal contact with homeowners because of the loss of service people.”

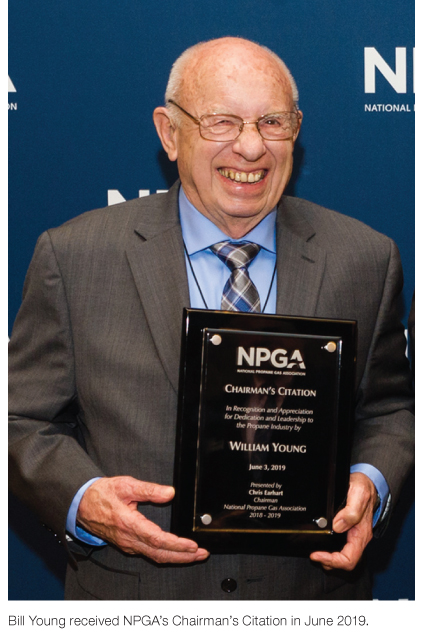

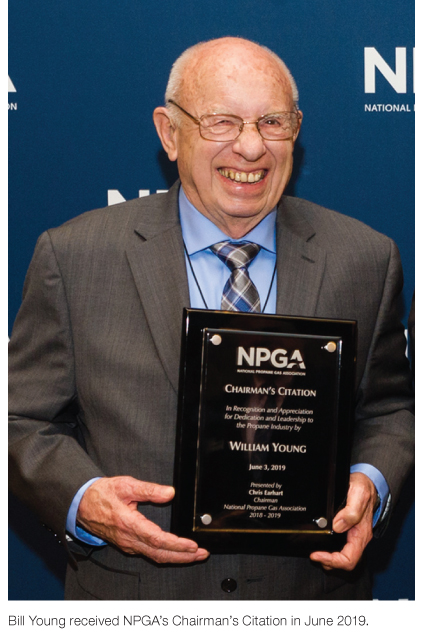

Over the years, Young has been honored by industry organizations. In 2003, he received the Personal Distinction Award from the Canadian Gas Association. The same year, he received a 40-year Participation award from the American National Standards Institute (ANSI). In 2017, he was named to the LP Gas Hall of Fame. This year, at the National Propane Gas Association (NPGA) Annual Meeting and Board of Directors Meeting in June, Young received a Chairman’s Citation for his service to the industry.

Throughout his career, too, Young has been an active member of industry organizations. He has served on ANSI committees for more than 45 years; he has been an active member of NPGA for more than 45 years; he has participated in that group’s Technology, Standards, and Safety Committee for more than 30 years; and Young has served on numerous National Fire Protection Association (NFPA) committees for 25 years. He has also testified in front of government entities to help lift propane restrictions and create and improve standards.

A Keen Interest

“I do have a keen interest in voluntary consensus codes,” Young says. “They allow an average person a chance to discuss safety and actually be heard.”

“Unfortunately, I see fewer and fewer people from the propane industry joining these groups,” he adds. “There are many Canadian Safety Association (CSA) groups who need members. Often, the meetings are held via video conference. This eliminates the travel costs and the living expense of having to attend a meeting.”

Just as Young says he had an unusual approach to college, he says codes should not require one, defined approach.

“My friend Jim Stannard, who passed away a few years ago, always cautioned that we are not making a cookbook,” Young says. “Codes should state the objective, but not the route. We have those who want the codes to be too explicit—like suggesting that you must put on your left shoe before putting on the right shoe.” — Steve Relyea

(SOURCE: Butane-Propane News magazine, July 2019)

Young’s career in the propane industry started with a summer job painting cylinders while in college. A week after being hired, and after answering “yes” when asked if he could do mechanical work, he completed his first propane conversion on a lift truck. As the end of summer neared, his employer asked if he would consider staying on and going to night school.

Young’s career in the propane industry started with a summer job painting cylinders while in college. A week after being hired, and after answering “yes” when asked if he could do mechanical work, he completed his first propane conversion on a lift truck. As the end of summer neared, his employer asked if he would consider staying on and going to night school.A Key Player

He did. More than half a century later, after working in several positions in the industry, Young is vice president of engineering for Superior Energy Systems (Columbia Station, Ohio). Over the years, he has served as a key player in the sale, design, engineering, construction, manufacture, and service of propane gas equipment.

His studies in college were varied, too. “I had an unusual approach to college,” Young recently told BPN. “I studied whatever interested me.” Between 1959 and 1965, at Youngstown University and the University of Pittsburgh, that included the basic sciences, mathematics, creative writing, philosophy, and music. Later he took a host of engineering courses. “As a consequence, I have 148 hours between Youngstown and Pitt,” he says. (Generally, 120 hours is enough for a bachelor’s degree.) “However, none of those things resulted in a degree. My wife once suggested I had become a professional student.”

Long, Varied Career

After accepting the offer to stay on at the propane company, Young’s long and varied career really got underway. The company he started with was Industrial Gases, a small independent propane company in Pittsburgh. The man who assigned him that first propane conversion and later asked him to stay on was the company’s president, Jerry Apt. Young became staff engineer in 1961.

“Industrial Gases had no domestic customers; we supplied industry only,” Young says. “As a small company, we shared duties as required. We drove trucks, filled cylinders, did service work, made sales calls, developed advertising, and designed systems. It was a wonderful place to work.”

While at Industrial Gases, Young and others performed hundreds of forklift truck conversions. They also converted several fleets of trucks to operate on propane fuel. All their personal vehicles ran on propane too. Young purchased his first new car—a 1962 Oldsmobile 88—and within two weeks it was running on propane. “I had propane vehicles continuously until 1983, when my wife asked if our next car could have a usable trunk.”

Many Interesting Things

At Industrial Gases, Young and others tried many interesting things. They worked with U.S. Steel to develop heated railroad cars to deliver hot tar to customers. They worked with oil well drillers to provide propane/air mixtures at 250% UFL (upper flammability limit) to allow drilling into gas-bearing sands in certain counties in Pennsylvania. They purchased a small fleet of old twin-barrel trailers and then delivered propane fuel to oil well rigs by simply exchanging trailers.

In 1965, Industrial Gases was acquired by Ugite, a propane subsidiary of UGI Corp. Young managed a district and then became sales manager of Ohio. He was also a representative of APCO (Applied Engineering Co.), a major manufacturer of propane vaporizers and propane/air mixers for standby fuel. Ugite transitioned to AmeriGas, and Young became manager of specialty sales and engineering (sales and construction of standby fuel systems for the U.S.).

In 1977, Young resigned from AmeriGas and became vice president of sales and engineering for Alternate Engine Systems, a manufacturer of propane vaporizers and propane/air blenders and mixers.

“I missed the closeness of smaller companies,” he explains. The operations manager offered a raise and then a company car. When Young still said no, the manager asked why he was leaving. That’s when he answered that he no longer whistled on his way to work. “There was a pause, then he said, ‘That’s the best reason I ever heard for resigning a job.’”

A Fun Time

Joining Alternate Energy Systems was like returning to Industrial Gases. “The people were delightful, and everyone pushed to make it successful,” Young explains. “[Owner John Hallberg] had great vision and was outstanding at developing concepts. I was good at taking concepts and developing usable products. It was a fun time.”

While there, Young developed many automatic controls for systems, which allowed self-adjustment to maintain fuel quality. He and Hallberg worked on Hallberg’s POM (piston operated mixer) mixing valve. “It is so simple, yet accurate,” Young says. Young also designed and sold an ethane vaporizer to a steel company that was hoping to have available quantities of liquid ethane for fuel. “We were in the early stages of the energy crisis, and sales were good,” he explains. They also started an affiliate construction company, Alternate Energy Installations in Ohio. In 1983, Young became company president.

In 1989, Young left Alternate Energy Systems and worked at a nearby design/build contractor that specialized in propane systems. Over the next decade, he and the company designed and installed many natural gas utility peak shaving plants.

“All It Took Was Dedication”

“All It Took Was Dedication”In 2002, Young and a small group started Superior Energy Systems and procured the assets of his previous employer. “We had the personnel, we had the contacts, and we had the knowledge to succeed,” he says. “All it took was dedication.” Today, Superior Energy Systems is one of the leading engineering, procurement, and construction contractors for natural gas liquids.

After being contracted to supply and install a number of auto fuel dispenser packages, and seeing they seemed relatively simple to build, Superior Energy Systems started manufacturing dispensers. Today, the company manufactures a wide range of propane autogas dispensing systems.

“Alliance AutoGas opened up a much larger market for us for dispensers,” Young says. “It was easier to have Alliance handle distributing the information on our behalf. The driving force behind propane autogas was my partner Donald Fernald. He has an astute view of future trends.”

Then and Now

Looking back at the previous 55-plus years, Young says there are two differences between then and now that really stand out.

One involves equipment design: “Over the years, there have been many changes in equipment design,” he says. “When I started, all of the control instruments were pneumatic. We went from pneumatic to digital and from digital to PLC (programmable logic computer). In earlier days, control instruments were grouped around each process. Now a central PC connects with a number of remote PLC systems, which allows remote monitoring and control if needed.”

The second change involves propane marketers: “Propane companies are far different now than when I first worked in the industry. Few propane companies have servicemen for appliance work. The only concern is to deliver gas. While I have no vast knowledge of the domestic business, I believe that marketers have lost most of the personal contact with homeowners because of the loss of service people.”

Over the years, Young has been honored by industry organizations. In 2003, he received the Personal Distinction Award from the Canadian Gas Association. The same year, he received a 40-year Participation award from the American National Standards Institute (ANSI). In 2017, he was named to the LP Gas Hall of Fame. This year, at the National Propane Gas Association (NPGA) Annual Meeting and Board of Directors Meeting in June, Young received a Chairman’s Citation for his service to the industry.

Throughout his career, too, Young has been an active member of industry organizations. He has served on ANSI committees for more than 45 years; he has been an active member of NPGA for more than 45 years; he has participated in that group’s Technology, Standards, and Safety Committee for more than 30 years; and Young has served on numerous National Fire Protection Association (NFPA) committees for 25 years. He has also testified in front of government entities to help lift propane restrictions and create and improve standards.

A Keen Interest

“I do have a keen interest in voluntary consensus codes,” Young says. “They allow an average person a chance to discuss safety and actually be heard.”

“Unfortunately, I see fewer and fewer people from the propane industry joining these groups,” he adds. “There are many Canadian Safety Association (CSA) groups who need members. Often, the meetings are held via video conference. This eliminates the travel costs and the living expense of having to attend a meeting.”

Just as Young says he had an unusual approach to college, he says codes should not require one, defined approach.

“My friend Jim Stannard, who passed away a few years ago, always cautioned that we are not making a cookbook,” Young says. “Codes should state the objective, but not the route. We have those who want the codes to be too explicit—like suggesting that you must put on your left shoe before putting on the right shoe.” — Steve Relyea

(SOURCE: Butane-Propane News magazine, July 2019)