(September 22, 2020) — Unlike a lot of businesses in the U.S. struggling because of COVID-19, 15 propane truck suppliers BPN spoke with have done relatively well in the past few weeks and months. Sure, there have been setbacks and challenges: “Ford was out for six weeks and that slowed us down some. It put us behind the eight ball but we’re working fast to finish things in time for winter,” said John Hawkins, CEO of H&H Sales (Huntertown, Ind.).

(September 22, 2020) — Unlike a lot of businesses in the U.S. struggling because of COVID-19, 15 propane truck suppliers BPN spoke with have done relatively well in the past few weeks and months. Sure, there have been setbacks and challenges: “Ford was out for six weeks and that slowed us down some. It put us behind the eight ball but we’re working fast to finish things in time for winter,” said John Hawkins, CEO of H&H Sales (Huntertown, Ind.).

“We are having a steady year producing vehicles in a timely fashion, meeting customer deadlines,” said Mike VanDenBoom, president of Signature Truck Systems (Clio, Mich.). “Our U.S.-based supply chain has helped keep lead time of parts within reason. We implemented changes in our work environment to deal with COVID-19 and fortunately have not been impacted. One of the largest obstacles is processing of paperwork for new vehicle license plates with the individual state Departments of Motor Vehicles.”

Wayne Terpstra of Custom Truck One Source (Kansas City, Mo.) has noticed some parts suppliers closed for a few days at a time or just working four days a week on an ongoing basis. “Many have told me that business had dropped off during the March to June timeframe,” he said. “No trade shows or travel this year has been kind of strange, but most have invented new ways of getting their sales messages out by enhancing their company website as Custom Truck One Source has.”

Wayne Terpstra of Custom Truck One Source (Kansas City, Mo.) has noticed some parts suppliers closed for a few days at a time or just working four days a week on an ongoing basis. “Many have told me that business had dropped off during the March to June timeframe,” he said. “No trade shows or travel this year has been kind of strange, but most have invented new ways of getting their sales messages out by enhancing their company website as Custom Truck One Source has.”

“The COVID epidemic has certainly brought on challenges in the supply chain with chassis and steel deliveries,” said Tim Schweppe, general manager of the Propane Division for Arrow Tank and Engineering (Minneapolis). “Thank goodness we had most of the inventory ordered and on-hand several months and sometimes up to a year or better in advance. That said, it has been a balancing act to get everything flowing through production, timing chassis receipts, and most importantly in the hands of our customers when expected. Communication with vendors on a regular basis is key and the information received is a moving target week-to-week.”

“We were back on track after a slowdown in orders March through May,” said Jason Soulon, regional sales manager for Westmor Industries (Morris, Minn.). “We were back on track by June and things were moving along again at a normal pace. We were fortunate to have a number of chassis already on hand, but several orders were delayed and we are just now receiving the last of the late chassis.” Soulon noted that social distancing, regular wipe downs, and no longer sharing tools have been some of the new guidelines in the production facility. “We are more spaced out at meetings and more meetings are held virtually. This seems to be working,” he said.

TANK SIZES AND FEATURES ARE HOT TOPICS

As it became clear that the business of building and selling propane trucks was not going to be slowed dramatically by COVID-19, the focus on what tank sizes are best for bobtails and transports and what features are popular on all trucks was back in full gear by mid-summer…and the race to fulfill orders ahead of winter continues to rage. White River Distributors’ (Dallas) executive vice president Danny McElroy said, “It used to be that cookie-cutter propane trucks were accepted by the masses. There weren’t a lot of options to customize the truck in terms of tank size, features, or very much else. Those days are over.” According to McElroy, White River Distributors no longer stocks bobtail barrels under 3000 gallons. “If someone wants a 2600 or 2800, we will still obtain it and work it into the line as quickly as possible, but demand for these is down. There has been some demand for bobtails that hold 5000 gallons or more, but the demand is not as big as in the last few years.”

Mississippi Tank’s (Hattiesburg, Miss.) Bobby Threatt, engineering manager, agrees with McElroy on the demand for larger barrels. “They’ve gotten steadily bigger over the years,” Threatt said. “More are staying away from the smaller.” He also agreed on the customization interest of customers. “It used to be bobtails were all white with very similar cabs, but now we’re seeing designs and decals, often matching the designs and decals of a large transport truck. We’re offering customization of trailers, lights, custom parts, and chrome bumper covers,” Threatt added. “The big transport trucks have also gotten away from stock-looking transports,” he added. “They are flashier and prettier. It is hard to buy a vehicle with just roll-up windows, cloth seats, and vinyl flooring anymore. Trucks with larger cabs are useful to fit computer systems and printers in.”

“The most common sizes for us are 3000- and 3200-gallon bobtails,” said Arch Hudelson, special projects director, western region at Ransome Mfg. (Fresno, Calif.). “The basic difference is the 3200-gallon vessel requires an 8-inch-longer wheelbase. This is not as much a liability for turning radius as it used to be.” According to Hudelson, today’s truck chassis offer much tighter turning radius than displayed in vehicles manufactured in prior decades. Therefore, the 3200-gal. vessel optimizes delivery capacity, while maintaining less than a 12,000-lb maximum on the steer axle and at, or under, the 20,000-lb maximum on the drive axle. “Additionally, the newest chassis provide superior engine power output levels that can easily accommodate adverse grades and conditions at maximum weight capacities. The truck manufacturers have reacted to market expectations in a wide variety of scenarios,” Hudelson added.

“Ransome has other customers that require vessels in the 2600- to 2800-gallon water capacity range,” Hudelson said. “These vessels are 72 inches in diameter and provide a much tighter aspect ratio for fitting into close areas. There are domestic and retail locations where the largest vehicle traveling in the area is a propane bobtail. We have viewed our vehicles pulling into domestic fuel deliveries and the natural vegetation just fits around the propane vessel. The smaller diameter makes a substantial difference in locations like this.”

“On the smaller side of the vessel size spectrum, we fabricate delivery vessels in the 1200- to 1300-gallon range for chassis in the ‘Class 5’ GVW capabilities,” Hudelson said. “These would include the Ram 5550 and the Ford F-550 Super Duty chassis. Most of these vehicles are configured in a 4WD setting and are used for severe weather deliveries or off-road situations. This would include wind machine fuel deliveries and other frost control heat applications. The 2WD vehicle up-fits in this vessel size range are typically used for delivering to RV campgrounds or small companies with LPG forklifts and no space for their own refueling vessel on site.”

Hudelson said that some of these chassis are designed for tank/body swap-out configurations, where the LPG vessel may be easily removed and a flatbed/crane body may be rapidly installed. “There are merits for ‘dual-duty’ vehicle operations and they are working out very well in ‘real world’ delivery situations.”

“On the other end of the spectrum, we have the bobtails that offer 5000-gallon water capacity or larger on a straight truck chassis,” Hudelson pointed out. “The chassis will be a Class 8, three-axle vehicle and, where individual states allow, a lift axle is generally required. These large bobtails are the right size for delivery situations where a 3200 bobtail isn’t large enough, but a transport semi is too large or the vessel being delivered to can’t accept a semi-load. A lot of these larger bobtails are used for metered delivery service in agricultural markets.”

Westmor Industries’ Soulon said he generally sees bobtail sizes as smaller in the South where there is less overall demand for propane and larger in higher-demand areas such as the North Central and Northeast. “In addition to the smaller sizes, Westmor offers a 5500-gallon as well as a 5300-gallon bobtail. The 5300-gallon tank is an 80-inch diameter whereas the 5500-gallon tank is 84 inches in diameter.,” Soulon said. “A 6400-gallon tank is also offered, which is built with lighter steel to offset the heavier payload. Typically, this truck is used more for large farms than for residential deliveries.”

TWEENER-BOBTAILS, DRIVE-AWAY PREVENTION, AND MORE INNOVATIONS

“Thinking outside the box is synonymous with new product development at Arrow Tank and Engineering Co.,” said Tim Schweppe, general manager, propane division. “When it comes to expanding our product line, we consider the industry norm and ask ourselves why? Likewise, we also apply this process when evaluating our current products such as bobtails.” Schweppe said that a Midwest customer who currently owns both single-axle and tandem-axle bobtails in 80-in. diameter only knows the manner and efficiencies of these bobtails unless something different is offered.

“Many folks express their satisfaction with tandem axle efficiencies, but reluctantly opt for a single-axle bobtail due to length and maneuverability. This is where we initiate the ‘tweener bobtail’ (short for in-between) conversation,” Schweppe said. “Credit is really due to Andy Johnson of Lin’s Propane Trucks as this concept has worked very well for their bobtails operating on the tight roads of the northeastern states. If it works on a goat trail in New England, then there is no reason it cannot work for residential delivery in the Midwest.”

“The most popular tweener in our neck of the woods is a 5000-gallon, 84-inch-diameter tank mounted on a wheelbase that is a mere 8 inches longer than the typical 3400-gallon single axle,” Schweppe said. “Or simply 1600 added gallons by adding 8 inches to the wheelbase. We recently captured some overhead drone video that is published on Arrow’s YouTube Channel that illustrates this maneuverability better than any words can describe.”

Here is data using a Freightliner M2 as an example:

Cargo Tank Wheel Base Overall Length Turning Radius

5000/84 224 in. 31.1 ft 30.0 ft

3400/80 216 in. 26.9 ft 27.8 ft

+1600 WG +8 in. +4.2 ft + 2.2 ft

Steve Bloomstrand of Rocket Supply (Roberts, Ill.) said that the 3200-gal. tank is the most popular, but that the 3400-gal. tank is growing in popularity. “We’re not seeing a lot of movement to the 5000-gallon truck in the Midwest. They are more popular out West where routes are typically longer.” Bloomstrand said he and his customers have been pleased with a proprietary electrical system in his trucks that is popular in police and fire vehicles. “This system is easy to diagnose,” he said. “We are also happy with our mandrel-bent welded plumbing, which cuts the number of turbulence points where joints are. It allows for cleaner flow and less leaking at joints.”

“Computerization, electronics, communication with back-office software, and the knowledge of how to integrate it all into the vehicle with internet connectivity are all features that are seeing a lot of demand,” said Brian Amthor, executive vice president of Amthor International (Gretna, Va.). “With connectivity, drivers can locate the nearest dealership when needed.” As for tank sizes, Amthor builds a lot of 3000-gal. and 3200-gal. bobtails. “We are getting a few more 5000- to 6000-gallon units,” Amthor said. “Working with a lot of oil companies, we do a lot of crossover business with oil companies also in the propane business.”

Tim Thrash, sales manager at JARCO (Salem, Ill.) said they promote powder-coated barrels, an industry exclusive they describe as superior to traditional liquid paint. They also promote stainless-steel tank rails, described as superior material to traditional carbon steel. In addition, Thrash described a few things the company is doing differently this year: “We’re offering flanged stainless-steel piping that is polished and passivated. There are no leaks and virtually no maintenance is required on piping. We have flanged MEC valves with no leaks in piping, auxiliary fill line and front vapor connection, and a safety system on direct-fill connection and hose-end valve.”

At Kurtz Truck Equipment (Marathon, N.Y.) Roger Smith, general manager and vice president of marketing, propane sales, noted several popular features for bobtails include strobe lights on all sides to draw attention to the vehicle at night and brake interlock systems to prevent drive-aways. “Insurance companies will give better rates for companies that take precautions against drive-aways,” Smith explained. “Sometimes a driver accidently pulls down an entire loading rack. The last thing anyone wants to see is a truck pull-away.” He noted Kurtz Truck has also done several trucks with enclosed rear decks, “This has been particularly popular for customers in Canada and other excessively cold areas.”

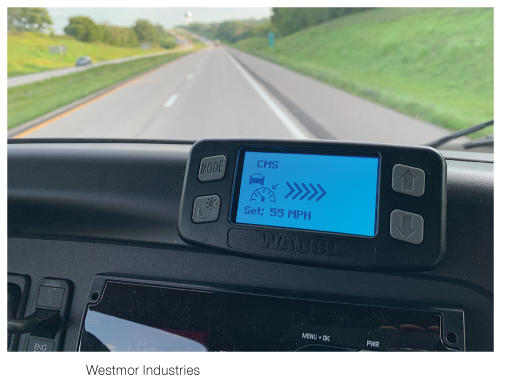

Other safety features are becoming popular with propane companies as well as their insurance providers. “There are three companies—Bendix, Meritor, and Detroit Diesel—that have developed collision mitigation systems (CMS),” said Westmor Industries’ Soulon. “The CMS system tracks your speed and the speed of vehicles in front of you. If a vehicle in front of you hits the brakes, the system will warn you and if you don’t take corrective action the system will reduce speed and apply the brakes if needed.” Another technology, Lane Departure Warning systems, warn the driver with audible and visual alerts if the vehicle is drifting out of its lane. Soulon also mentioned Zone Defense, which provides back-up camera systems. These systems are also available with obstacle-detection sensors for warning drivers of objects behind the vehicle.

FISK Tank Carrier (Columbus, Wis.) mainly builds boom trucks for the propane industry. “There has been a lot of interest in the Ford 7.3-liter V8 engine, which can be converted to run on propane,” said Josh Budworth, director of sales and operations. “The F-550 and F-600 tank setting trucks can carry up to two 1000-gallon tanks. There is a lot of efficiency to be gained with these trucks over trailers. It allows the operator to stock the trucks for a full day of work and not have to drive back in the middle of the day to restock them…only to pick up tanks and continue going.”

Ed Hoffmann, president of Blossman Services (Ocean Springs, Miss.), the distribution partner for Alliance Autogas, commented, “There is a lot of interest in the Ford 7.3-liter V8 engine bobtail that can run on propane. The barrel will be 3000 gallons and the tank for fueling the bobtail will hold 54 usable gallons. The truck is late in production, but expected in September.”

BIGGER TRUCKS = BIGGER TAXES, BUT EFFICIENCY MAY BE WORTH IT

Custom Truck One Source’s Terpstra said 3200-gal., 3400-gal., and 3499-gal. tanks are the most popular sizes right now as retailers move to larger sizes to get more efficiency and so they can get more stops in before having to go back and reload the truck. “Depending on where the retailer is and bridge laws, some are looking at 5000-gallon tanks on tandem chassis. The only issue for the 5000-gallon tanks and larger is the retailer is going to pay a 12% federal excise tax.”

Kurtz Truck’s Smith is seeing a little more demand for the 5000-gal. or larger bobtail trucks. Like Terpstra, he mentioned the 12% federal excise tax but said most counties in New York also charge 8%, which takes the full tax to 20%. “Not a small amount on trucks that often cost over $200,000.” In the Northeast, the large bobtails are selling to a few customers who deliver on the edge of the Boston suburbs, Smith noted. “In the more rural areas in New England with small, dirt driveways, the bobtails tend to be smaller,” he said. “Companies don’t make any money with drivers dead-heading back to the storage tank in the middle of the afternoon, so computer routing systems to maximize efficiency are popular these days.”

SHAPES AND FEATURES ARE BIG FACTORS

BPN talked with Gerald Pearson of Exosent (College Station, Texas) by phone while he was at the Pacific Propane Gas Association Trade Show in Sunriver, Ore., one of the few in-person industry events so far in 2020. “There is an excellent turnout considering the circumstances. We’re excited to share our bobtails and transport trucks because of their unique shapes that are safer due to their lower center of gravity,” Pearson said. “We’re building more and more 4156-gallon bobtails and there is interest in the 5000-gallon, and 5500-gallon bobtails. These vehicles have three axles. Our transport trucks include the first seven-axle unit for Michigan, which allows jumbo-size transport trucks that haul 17,000-plus gallons. Aerodynamic wings, windskirts on the sides, and enclosed plumbing are features that stop wind from going under the front and increase fuel economy.” Pearson said that Exosent’s trucks are becoming more popular as more trucks are out in the field gaining attention.

“With the ever-changing world as we know it today and our new transport truck division in place, Arrow Tank and Engineering Co. is doing the same to better serve our customers and be ready for whatever is next,” said Nate Jacobsen. “We have spent a lot of time developing and fine-tuning our trailers. Our designs are a more universal layout, which allows us to be flexible and adapt to both customer needs and industry needs quickly.”

“We have been busy the last several months ‘getting our ducks in a row’ with the addition to our trailer product line, which now includes 10,600-to 14,600-gallon LPG/NH3 transport trailers; any size LPG/NH3 refurbishment and recertifying; code repair/modification/alteration/stretching; meter delivery LPG transport trailer; self-contained hydraulic system for pump; and all stainless steel framing and appurtenances.”

“We are seeing an increase in demand for the larger 8-axle transports in Michigan,” said Signature Truck’s VanDenBoom. “These jumbo transports allow for legally carrying nearly 18,000 gallons, which reduces the number of trips to the terminal. This obviously reduces the cost of transporting propane or butane. These trailers are designed and engineered with many safety features to safely carry these large quantities.”

JARCO’s Thrash said that in addition to their powder-coated barrel, exclusive to the industry, and stainless steel undercarriage, there has been a change to the company’s transport trailer piping, which has always been stainless steel. “In the past year we have made the change to using the Marshall Excelsior (MEC) ‘Sweeps’ piping and MEC Flanged Valves in our stainless steel piping.”

Westmor Industries’ Soulon said one more innovation for the transports that the company had planned to display at the Southeastern Propane Expo in Nashville in April was a metered delivery system. “This can provide a benefit for those who deliver directly to a commercial account from the transport,” Soulon said. — Pat Thornton