Paints and coatings are fundamental to safety, long-term durability and regulatory compliance to industries worldwide. Beyond acting as a protective layer, propane tank coatings coatings increasingly serve as functional enablers that improve manufacturability, enhance energy efficiency and support evolving environmental goals.

As United States regulations evolve and the propane industry continues to balance efficiency, safety and environmental responsibility, coating technologies are important tools at the industry’s disposal. The right coating system can extend tank life, reduce maintenance costs, improve corrosion resistance and ensure adherence to regulatory standards. This article explores how coatings support performance, compliance and sustainability across both stationary tanks and portable cylinders.

Enhancing Performance of Propane Tanks

Propane tanks encounter a variety of harsh conditions: UV exposure, moisture, soil chemistry, temperature cycling and mechanical impacts during transport or servicing. Corrosion under insulation can also be a problem. These stresses make coatings essential for both aboveground and underground propane tanks.

Aboveground tanks benefit from a combination of coatings to maintain integrity and appearance over time. A zinc-rich primer coating is often used for sacrificial protection from corrosion, followed by an epoxy barrier layer, with a polyurethane topcoat providing UV protection and scratch resistance. Overall, coatings systems are designed to offer strong adhesion and protection against weather, abrasion and chemical exposure. Beyond protection performance, coating properties such as fast-curing or requiring minimal surface preparation can significantly reduce downtime where repainting or repair is required.

Portable cylinders have their own performance demands. They are frequently handled, transported and therefore more subject to abrasion. Coatings that resist chipping and impact damage can extend service lives and reduce the frequency of failures. In all cases, selecting coatings engineered for the tank’s specific environment helps ensure consistent performance and reliable service.

Meeting U.S. Compliance & Safety Standards

The U.S. propane industry operates under a well-defined set of codes and regulations that directly influence coating requirements.

For stationary tanks, the core reference is the National Fire Protection Association (NFPA) 58 Liquefied Petroleum Gas Code. Its requirements cover corrosion protection for underground tanks to the conditions under which a container may be filled. Proper coating application is integral to compliance, particularly in preventing or mitigating corrosion that could compromise tank integrity. For underground installations, NFPA 58 mandates corrosion protection systems and requires periodic testing and documentation of cathodic protection performance. Tanks that do not meet corrosion protection standards may not be filled until the issue is resolved.

Transport cylinders fall under U.S. Department of Transportation regulations, which require cylinders to meet specific material, construction and maintenance standards. Cylinders must be visually inspected before filling and any evidence of corrosion, pitting or physical damage can disqualify them from service. High-quality coatings play a preventive role by minimizing corrosion and helping cylinders pass these visual inspections consistently.

Environmental regulations also influence coating choices. The Environmental Protection Agency’s (EPA) rules for architectural and industrial maintenance coatings include nationwide limits on volatile organic compound (VOC) emissions.

These rules have driven the widespread adoption of lower VOC, waterborne, powder and high solids coating systems. In addition, some U.S. states, such as California, impose stricter VOC limits that manufacturers and applicators must consider when selecting products.

The regulatory climate around PFAS-containing chemicals is also tightening. PFAS are long-lasting chemicals — sometimes called “forever chemicals” — with components that break down very slowly over time. As federal agencies expand reporting, designation and cleanup requirements for certain PFAS, many coating manufacturers are reformulating products to eliminate these substances. PFAS-free coatings are a lower-risk, future-proof option.

Supporting Long-term Environmental Goals

Sustainability in propane tank coatings manifests in several areas: emissions reduction, resource efficiency, recyclability and regulatory adaptability.Lower-VOC and low-hazard formulations reduce emissions during application and improve air quality, making them preferable for both environmental and worker safety reasons. They can also reduce ventilation requirements. This increases the desirability of waterborne and high solids powder coatings.

Durability is another sustainability dimension. Extending the lifespan of tanks and cylinders through better corrosion resistance reduces the frequency of repainting, blasting and transport, thereby lowering operational emissions and waste.

A coating system that extends the service life of a tank surface not only lowers life-cycle cost but also materially reduces environmental impact. Furthermore, coatings that do not inhibit the reusability and recyclability of propane tanks at end of life are also strongly desirable.

Finally, choosing coating technologies designed to comply with current and expected future regulations helps avoid costly reformulations or operational changes down the line. As PFAS-related rules evolve and as more regions adopt stricter VOC limits, the industry is recognizing the value of selecting coatings that are both high performing and regulatory resilient in the long term.

Looking Ahead

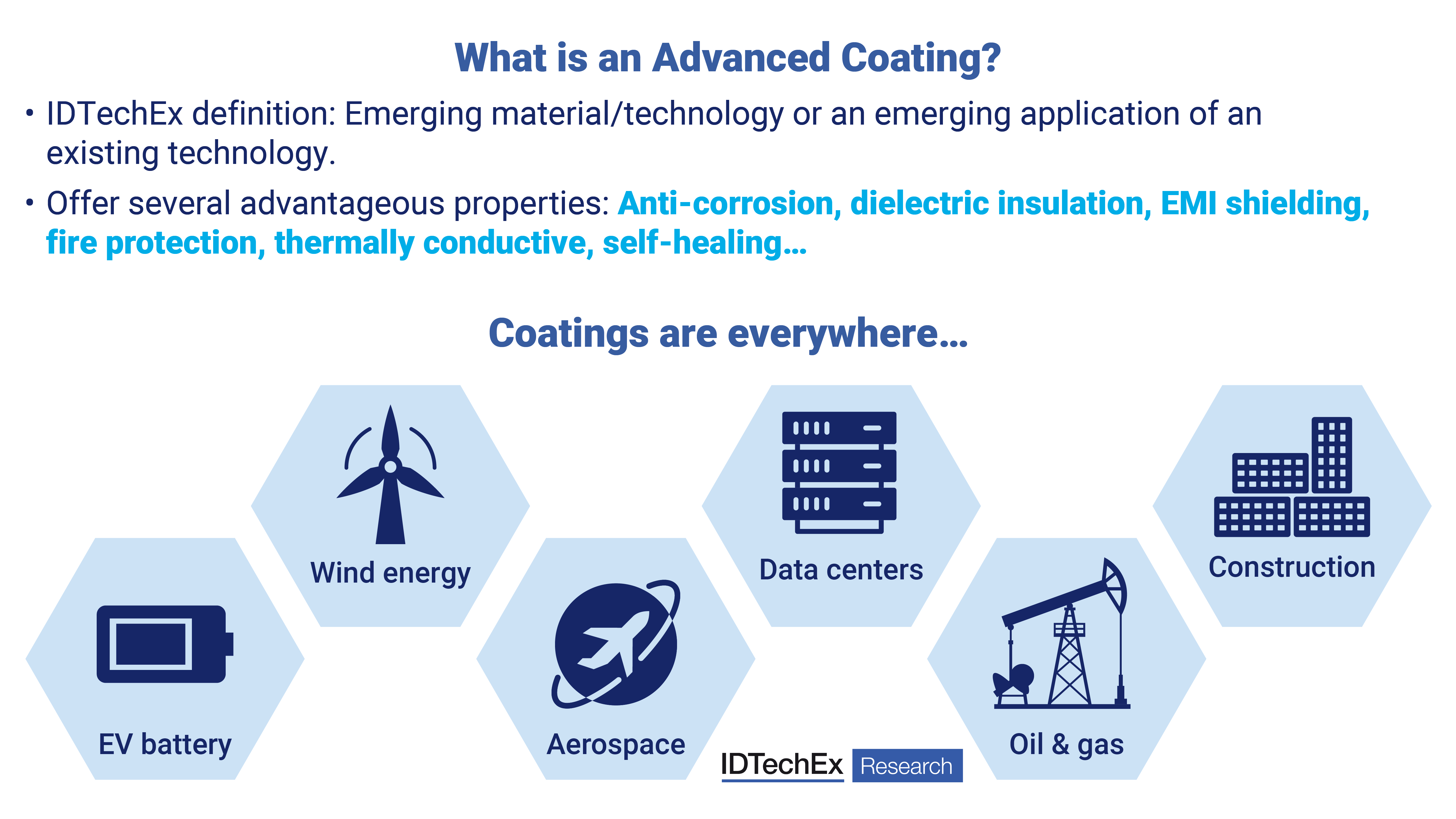

As performance expectations grow and regulatory pressures tighten, coatings will remain central to effective propane tank management. From extending tank life to supporting environmental goals, advanced coating systems offer real advantages for propane marketers, equipment suppliers and service providers.

The industry is well positioned to benefit from next-generation coating materials that deliver durability, compliance and sustainability — ensuring tanks remain safe, efficient and reliable across their full life cycle.