Wednesday, May 1, 2019

A walk through the massive annual Work Truck Show in Indianapolis in early March gave attendees a chance to discover almost every new development in the work truck world. Alternative fuels received a good deal of competitive spin regarding which fuel delivers the best bang for your buck now and in the future. Many speakers and seminars made their case that electric vehicles are the way of the future—or that clean diesel is the way of the future—the option of propane autogas wasn’t mentioned.

Meanwhile, an ever-growing group of stakeholders representing propane autogas begs to differ. This group, anchored by the Propane Education & Research Council (PERC), has steadily reserved more floor space at the Work Truck Show and they, too, want their message heard. “Education and awareness continue to be critical,” said Michael Taylor, director of autogas business development at PERC. “Many people are resistant to change, but we have been successful in convincing fleet managers that propane has a short-term return on investment, typically less than two years, and can provide the lowest total cost of ownership over the vehicle life.”

Meanwhile, an ever-growing group of stakeholders representing propane autogas begs to differ. This group, anchored by the Propane Education & Research Council (PERC), has steadily reserved more floor space at the Work Truck Show and they, too, want their message heard. “Education and awareness continue to be critical,” said Michael Taylor, director of autogas business development at PERC. “Many people are resistant to change, but we have been successful in convincing fleet managers that propane has a short-term return on investment, typically less than two years, and can provide the lowest total cost of ownership over the vehicle life.”

At PERC’s booth at the Work Truck Show, attendees were asked to “pin” their fleet profile—regardless of fuel type—on an in-booth map of the United States. All participants were eligible for prizes and were encouraged to make several “pit stops” throughout the booth to learn more about how propane autogas could help their fleet reach sustainability goals while cutting costs over the lifetime of the vehicle.

Taylor cited “clean diesel” and gasoline as two fuels that fleet managers are reluctant to switch from. “We can show the cost savings and we have numerous testimonials to back us up,” he said. “The environmental concerns remain despite the efforts to position ‘clean diesel’ and gasoline as free of contaminants,” noting that runoff can find its way into soil and water and cause serious contamination. Case studies on fueling with propane can be found at propane.com.

“Electric vehicles will likely find their niche with personal sedans and some Class 1 and 2 vehicles. There will be very limited success for EVs expected to handle significant payload or range. I expect there will continue to be limited additional adoption for electric school buses. Propane makes much more sense.”

On the following pages are some details on other stakeholders promoting propane usage who were at the Work Truck Show.

SUPERIOR ENERGY SYSTEMS AIMS TO HELP MAKE PUBLIC REFUELING A REALITY

Superior Energy Systems (SES; Columbia Station, Ohio) displayed a propane autogas dispenser at the Work Truck Show. Having worked exclusively in propane since 1975, the company has sold more than 1100 dispensers to customers in all 50 states and throughout Canada. Projects have ranged from very small dispenser installations to massive midstream infrastructure installations such as the Crestwood Terminal at Montgomery, N.Y., that can fill four transports in 17 minutes.

Several factors are currently helping to make public refueling a reality, including creating an opportunity for autogas customers to no longer be limited to refueling between 8 a.m. and 5 p.m., when an attendant is available. Superior and others have been working with the National Propane Gas Association’s Technology, Standards, and Safety Committee (TS&S) to make the K-15 connector safer and ease the requirement for glasses and gloves at refueling sites. “State propane associations in states such as Minnesota are also offering infrastructure rebates to help make public refueling sites available,” said Jim Bunsey, director of operations at SES. “We are getting to the point where a good portion of autogas users can drive up 24/7 and use their credit card to refuel.”

“While more environmentally-friendly and cost-effective, the goal is to make refueling with propane as user-friendly as it is to refuel with motor gas or diesel,” Bunsey said. In addition to the dispenser, Superior displayed a Propane Autogas Evacuation System that simply, safely, and efficiently removes autogas from fleet vehicles for service and maintenance. The system can be used with both liquid and vapor vehicle systems and operates completely on air using a pneumatic pump, with no engine, electricity, or switching of hoses.

ROUSH CLEANTECH’S SCHOOL BUS SUCCESS

ROUSH CLEANTECH’S SCHOOL BUS SUCCESS

ROUSH CleanTech displayed an F-550 chassis cab at its booth and a Ford F-750 propane-powered van body in the Propane Education & Research Council booth. While there wasn’t a school bus in sight, Ryan Zic, school bus sales director for ROUSH CleanTech, extolled the reduced emissions of the ROUSH bus compared to a diesel model manufactured before 2007. “Our engine is 90% cleaner than the current EPA standard,” Zic explained. “You would have to operate 100 of our propane autogas vehicles to emit as much NOx as one diesel bus manufactured before 2007.”

He wanted Work Truck Show attendees to take away the propane message—that alternative fuel vehicles offer a fuel option that substantially lowers NOx emissions. “Our school district customers are responding in a big way. With all the diesel emission scandal and maintenance system complexity, fleets are ready for a fuel that is clean, straightforward, and reliable.” Zic noted there are currently 14,000 propane school buses operating in more than 850 school districts in North America. “School fleets have been challenged over the past nine years with a tough, stop/start duty cycle and a complicated diesel emission system that struggles with excessive idle. The simple, passive emission system offered on our propane school buses was a huge motivator early on for fleets to switch away from diesel. That is still a major factor today, but, like the diesel emission system, our customers are evolving too,” Zic said. “We now have peers within school fleets sharing data on cost per mile of operation between propane and other fuels. They report savings from 15 to 30 cents per mile when compared to a diesel bus—some even more. Reducing the cost per mile of operation is quickly becoming as much a motivator as the simplicity of propane school bus operation.”

With strong gains in the U.S. and Canada, propane buses are gaining traction even in areas where alternative fuels have struggled in the past. “The Midwest, Central Plains, and remote provinces of Canada have been strong adopters of propane because of cold resilience and effective operational costs.” Zic also cited headway as more retail propane marketers engage in alternative fuel development by utilizing business development teams, promotions, marketing materials, vehicle incentives, and more. “When retailers engage like this, it really amplifies the propane autogas cause and makes potential buyers feel infinitely more comfortable in taking the next steps toward a propane fleet.”

FREIGHTLINER EXPANDS S2G OFFERINGS WITH NEW 8.8-LITER ENGINE

FREIGHTLINER EXPANDS S2G OFFERINGS WITH NEW 8.8-LITER ENGINE

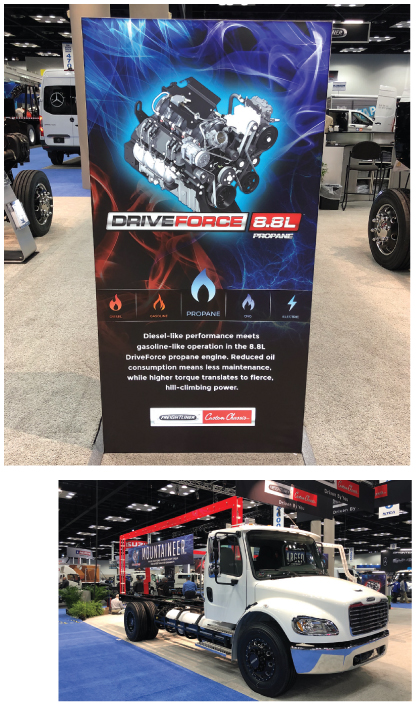

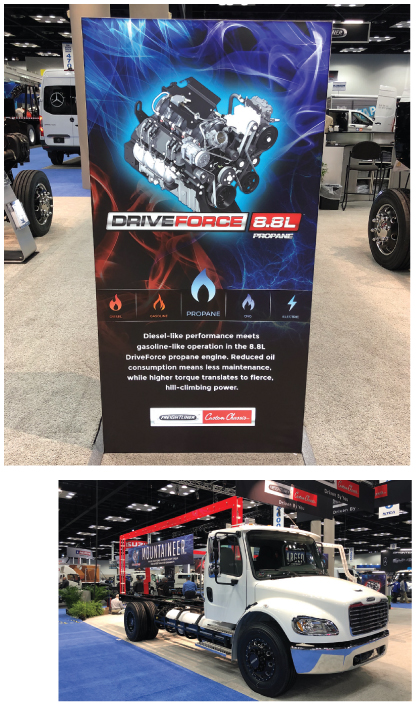

Freightliner Custom Chassis Corp. (FCCC; Portland, Ore.) utilized its presence at the 2019 Work Truck Show to showcase a new version of its S2G work truck powered by an 8.8-liter propane engine, part of FCCC’s DriveForce non-diesel engine line.

The S2G now comes with two engine options—an 8.0-liter as well as the new 8.8-liter—from FCCC’s DriveForce, its line of proprietary non-diesel engines for the commercial market. Touted as providing “diesel-like” performance and “gasoline-like” operation, FCCC says S2G delivery fleet owners can expect smooth, quiet, reliable power at lower operational costs.

The 8.8-liter DriveForce liquid propane engine offers 270 hp@2600 rpm, 565 lb-ft@1500 rpm, and is the only factory installed propane autogas engine available to the medium-duty market. Its front suspension offers up to a 55-degree wheel cut for industry-leading maneuverability, and a GVWR of up to 33,000 pounds.

The S2G has a 60-gal. LPG fuel tank, and Allison 2500RDS and 2550RDS automatic transmissions with PTO provisions available. The chassis comes with 3-year/50,000-mile warranty with towing and roadside assistance and 24/7 factory-direct customer support.

“The 8.8-liter propane engine…offers the torque and power of a diesel engine at near-idle RPM levels,” said Mike Stark, product manager for Commercial Chassis at FCCC. He told BPN that the new 8.8-liter DriveForce engine is designed with the terrain of a typical bobtail route in mind. “Customers were not as concerned about speed,” he said, “as they were about torque and reducing oil consumption.”

ALLIANCE AUTOGAS’ NEWLY RELEASED TECHNOLOGIES

Following a record number of technologies released in 2018, Alliance AutoGas (Swannanoa, N.C.) had a wealth of accomplishments to share at the Work Truck Show. This technology included a previously unreleased vehicle system in partnership with Prins Alternative Fuel Systems installed on a 2019 Chevy Silverado.

Examples of the new 2018 technologies include 58 new EPA certifications covering 38 different vehicle platforms, an electric/propane autogas hybrid Ford Fusion, and the aftermarket autogas port-fueled direct injection (PFDI) engineered system introduced last year for the 2018 Ford F-150 with the 3.3-liter V6 and the 5.0-liter V8. “We are pleased to differentiate Alliance AutoGas in the alternative fuel market as hybrid-friendly,” said Alliance AutoGas president Stuart Weidie. “This vehicle is a precursor of many to come in the Ford family.”

“While we aren’t doing a live conversion or a ride and drive at this year’s Work Truck Show, we have more to share than ever,” said Ed Hoffman, president of Blossman Services Inc. (BSI), Alliance’s technology distributor. “In 2018 we not only maintained our industry-leading portfolio of products, but also expanded into new technological realms.” Hoffman explained that all products were simple multi-point fuel-injected engines a few years ago while the company ran through R&D projects to better understand how they would interface with fuel systems of the future.

The Prins and Alliance-engineered system installed on the 2019 Chevy Silverado displayed in the PERC booth is estimated to save more than $3000 annually in fuel costs and result in an average reduction of 58 tons of greenhouse gas emissions. The vehicle was provided by Alliance AutoGas service center Dickinson Fleet Services, and was fully equipped with the Alliance AutoGas-engineered system.

ONE-STOP SHOPPING WITH ICOM NORTH AMERICA

ICOM North America (New Hudson, Mich.) has enjoyed dramatic growth in the past few years. “People are seeing the benefits of propane autogas and we’ve done a better job of aligning with partners to allow a ‘one-stop shopping’ approach for those wanting to make a switch to autogas,” said Albert Venezio, chairman of ICOM North America.

Four years ago, ICOM partnered with various propane industry stakeholders, including Industrial Propane Services (IPS), Signature Truck Systems, and several other retail propane marketers and service providers, to create United Propane Autogas Solutions (UPAS). According to Venezio, the partnerships have been critical to make “one-stop shopping” available. “We had to make it easy to partner with those who can provide all components of the autogas program—the best retail marketers, competitive propane pricing, and the most ideal gas dispensing systems.”

It has expanded its dealer network to 150 in the U.S. and Canada, and is seeing growth in Mexico and Latin America. “We have the largest grouping of EPA and CARB certifications with a total of 500 certifications. We’re working with UPAS to bring about more shuttle buses, trolleys, work trucks, pickup trucks, vans, and law enforcement vehicles,” Venezio added.

NAFTC ADDS PROPANE-SPECIFIC CURRICULUM

The National Alternative Fuels Training Consortium (NAFTC) of West Virginia University was represented at the Work Truck Show by interim director Micheal Smyth, who met with a number of propane industry stakeholders. “We have many projects going,” Smyth said. “Fleets are adopting, autogas product upfitters are making much more robust and stable systems, and early adopters are feeling much more confident in their autogas vehicles.”

Smyth told BPN that NAFTC is currently creating several training projects for the Propane Education & Research Council (PERC). “We are putting a propane autogas training program online for first responders,” Smyth added. “We are creating education on how the vehicle works and what they need to know when they respond to an accident. In addition, NAFTC is preparing an online version of Propane 101. This should allow for shortening of technical training from a three-day to a two-day class if students do the Propane 101 online and replace some ‘dry lecture’ with a more interesting approach.”

NAFTC is also producing videos for PERC on autogas facility maintenance, tank purging at the commissioning, and how propane acts in the transfer process.

Meanwhile, an ever-growing group of stakeholders representing propane autogas begs to differ. This group, anchored by the Propane Education & Research Council (PERC), has steadily reserved more floor space at the Work Truck Show and they, too, want their message heard. “Education and awareness continue to be critical,” said Michael Taylor, director of autogas business development at PERC. “Many people are resistant to change, but we have been successful in convincing fleet managers that propane has a short-term return on investment, typically less than two years, and can provide the lowest total cost of ownership over the vehicle life.”

Meanwhile, an ever-growing group of stakeholders representing propane autogas begs to differ. This group, anchored by the Propane Education & Research Council (PERC), has steadily reserved more floor space at the Work Truck Show and they, too, want their message heard. “Education and awareness continue to be critical,” said Michael Taylor, director of autogas business development at PERC. “Many people are resistant to change, but we have been successful in convincing fleet managers that propane has a short-term return on investment, typically less than two years, and can provide the lowest total cost of ownership over the vehicle life.” At PERC’s booth at the Work Truck Show, attendees were asked to “pin” their fleet profile—regardless of fuel type—on an in-booth map of the United States. All participants were eligible for prizes and were encouraged to make several “pit stops” throughout the booth to learn more about how propane autogas could help their fleet reach sustainability goals while cutting costs over the lifetime of the vehicle.

Taylor cited “clean diesel” and gasoline as two fuels that fleet managers are reluctant to switch from. “We can show the cost savings and we have numerous testimonials to back us up,” he said. “The environmental concerns remain despite the efforts to position ‘clean diesel’ and gasoline as free of contaminants,” noting that runoff can find its way into soil and water and cause serious contamination. Case studies on fueling with propane can be found at propane.com.

“Electric vehicles will likely find their niche with personal sedans and some Class 1 and 2 vehicles. There will be very limited success for EVs expected to handle significant payload or range. I expect there will continue to be limited additional adoption for electric school buses. Propane makes much more sense.”

On the following pages are some details on other stakeholders promoting propane usage who were at the Work Truck Show.

SUPERIOR ENERGY SYSTEMS AIMS TO HELP MAKE PUBLIC REFUELING A REALITY

Superior Energy Systems (SES; Columbia Station, Ohio) displayed a propane autogas dispenser at the Work Truck Show. Having worked exclusively in propane since 1975, the company has sold more than 1100 dispensers to customers in all 50 states and throughout Canada. Projects have ranged from very small dispenser installations to massive midstream infrastructure installations such as the Crestwood Terminal at Montgomery, N.Y., that can fill four transports in 17 minutes.

Several factors are currently helping to make public refueling a reality, including creating an opportunity for autogas customers to no longer be limited to refueling between 8 a.m. and 5 p.m., when an attendant is available. Superior and others have been working with the National Propane Gas Association’s Technology, Standards, and Safety Committee (TS&S) to make the K-15 connector safer and ease the requirement for glasses and gloves at refueling sites. “State propane associations in states such as Minnesota are also offering infrastructure rebates to help make public refueling sites available,” said Jim Bunsey, director of operations at SES. “We are getting to the point where a good portion of autogas users can drive up 24/7 and use their credit card to refuel.”

“While more environmentally-friendly and cost-effective, the goal is to make refueling with propane as user-friendly as it is to refuel with motor gas or diesel,” Bunsey said. In addition to the dispenser, Superior displayed a Propane Autogas Evacuation System that simply, safely, and efficiently removes autogas from fleet vehicles for service and maintenance. The system can be used with both liquid and vapor vehicle systems and operates completely on air using a pneumatic pump, with no engine, electricity, or switching of hoses.

ROUSH CLEANTECH’S SCHOOL BUS SUCCESS

ROUSH CLEANTECH’S SCHOOL BUS SUCCESSROUSH CleanTech displayed an F-550 chassis cab at its booth and a Ford F-750 propane-powered van body in the Propane Education & Research Council booth. While there wasn’t a school bus in sight, Ryan Zic, school bus sales director for ROUSH CleanTech, extolled the reduced emissions of the ROUSH bus compared to a diesel model manufactured before 2007. “Our engine is 90% cleaner than the current EPA standard,” Zic explained. “You would have to operate 100 of our propane autogas vehicles to emit as much NOx as one diesel bus manufactured before 2007.”

He wanted Work Truck Show attendees to take away the propane message—that alternative fuel vehicles offer a fuel option that substantially lowers NOx emissions. “Our school district customers are responding in a big way. With all the diesel emission scandal and maintenance system complexity, fleets are ready for a fuel that is clean, straightforward, and reliable.” Zic noted there are currently 14,000 propane school buses operating in more than 850 school districts in North America. “School fleets have been challenged over the past nine years with a tough, stop/start duty cycle and a complicated diesel emission system that struggles with excessive idle. The simple, passive emission system offered on our propane school buses was a huge motivator early on for fleets to switch away from diesel. That is still a major factor today, but, like the diesel emission system, our customers are evolving too,” Zic said. “We now have peers within school fleets sharing data on cost per mile of operation between propane and other fuels. They report savings from 15 to 30 cents per mile when compared to a diesel bus—some even more. Reducing the cost per mile of operation is quickly becoming as much a motivator as the simplicity of propane school bus operation.”

With strong gains in the U.S. and Canada, propane buses are gaining traction even in areas where alternative fuels have struggled in the past. “The Midwest, Central Plains, and remote provinces of Canada have been strong adopters of propane because of cold resilience and effective operational costs.” Zic also cited headway as more retail propane marketers engage in alternative fuel development by utilizing business development teams, promotions, marketing materials, vehicle incentives, and more. “When retailers engage like this, it really amplifies the propane autogas cause and makes potential buyers feel infinitely more comfortable in taking the next steps toward a propane fleet.”

FREIGHTLINER EXPANDS S2G OFFERINGS WITH NEW 8.8-LITER ENGINE

FREIGHTLINER EXPANDS S2G OFFERINGS WITH NEW 8.8-LITER ENGINEFreightliner Custom Chassis Corp. (FCCC; Portland, Ore.) utilized its presence at the 2019 Work Truck Show to showcase a new version of its S2G work truck powered by an 8.8-liter propane engine, part of FCCC’s DriveForce non-diesel engine line.

The S2G now comes with two engine options—an 8.0-liter as well as the new 8.8-liter—from FCCC’s DriveForce, its line of proprietary non-diesel engines for the commercial market. Touted as providing “diesel-like” performance and “gasoline-like” operation, FCCC says S2G delivery fleet owners can expect smooth, quiet, reliable power at lower operational costs.

The 8.8-liter DriveForce liquid propane engine offers 270 hp@2600 rpm, 565 lb-ft@1500 rpm, and is the only factory installed propane autogas engine available to the medium-duty market. Its front suspension offers up to a 55-degree wheel cut for industry-leading maneuverability, and a GVWR of up to 33,000 pounds.

The S2G has a 60-gal. LPG fuel tank, and Allison 2500RDS and 2550RDS automatic transmissions with PTO provisions available. The chassis comes with 3-year/50,000-mile warranty with towing and roadside assistance and 24/7 factory-direct customer support.

“The 8.8-liter propane engine…offers the torque and power of a diesel engine at near-idle RPM levels,” said Mike Stark, product manager for Commercial Chassis at FCCC. He told BPN that the new 8.8-liter DriveForce engine is designed with the terrain of a typical bobtail route in mind. “Customers were not as concerned about speed,” he said, “as they were about torque and reducing oil consumption.”

ALLIANCE AUTOGAS’ NEWLY RELEASED TECHNOLOGIES

Following a record number of technologies released in 2018, Alliance AutoGas (Swannanoa, N.C.) had a wealth of accomplishments to share at the Work Truck Show. This technology included a previously unreleased vehicle system in partnership with Prins Alternative Fuel Systems installed on a 2019 Chevy Silverado.

Examples of the new 2018 technologies include 58 new EPA certifications covering 38 different vehicle platforms, an electric/propane autogas hybrid Ford Fusion, and the aftermarket autogas port-fueled direct injection (PFDI) engineered system introduced last year for the 2018 Ford F-150 with the 3.3-liter V6 and the 5.0-liter V8. “We are pleased to differentiate Alliance AutoGas in the alternative fuel market as hybrid-friendly,” said Alliance AutoGas president Stuart Weidie. “This vehicle is a precursor of many to come in the Ford family.”

“While we aren’t doing a live conversion or a ride and drive at this year’s Work Truck Show, we have more to share than ever,” said Ed Hoffman, president of Blossman Services Inc. (BSI), Alliance’s technology distributor. “In 2018 we not only maintained our industry-leading portfolio of products, but also expanded into new technological realms.” Hoffman explained that all products were simple multi-point fuel-injected engines a few years ago while the company ran through R&D projects to better understand how they would interface with fuel systems of the future.

The Prins and Alliance-engineered system installed on the 2019 Chevy Silverado displayed in the PERC booth is estimated to save more than $3000 annually in fuel costs and result in an average reduction of 58 tons of greenhouse gas emissions. The vehicle was provided by Alliance AutoGas service center Dickinson Fleet Services, and was fully equipped with the Alliance AutoGas-engineered system.

ONE-STOP SHOPPING WITH ICOM NORTH AMERICA

ICOM North America (New Hudson, Mich.) has enjoyed dramatic growth in the past few years. “People are seeing the benefits of propane autogas and we’ve done a better job of aligning with partners to allow a ‘one-stop shopping’ approach for those wanting to make a switch to autogas,” said Albert Venezio, chairman of ICOM North America.

Four years ago, ICOM partnered with various propane industry stakeholders, including Industrial Propane Services (IPS), Signature Truck Systems, and several other retail propane marketers and service providers, to create United Propane Autogas Solutions (UPAS). According to Venezio, the partnerships have been critical to make “one-stop shopping” available. “We had to make it easy to partner with those who can provide all components of the autogas program—the best retail marketers, competitive propane pricing, and the most ideal gas dispensing systems.”

It has expanded its dealer network to 150 in the U.S. and Canada, and is seeing growth in Mexico and Latin America. “We have the largest grouping of EPA and CARB certifications with a total of 500 certifications. We’re working with UPAS to bring about more shuttle buses, trolleys, work trucks, pickup trucks, vans, and law enforcement vehicles,” Venezio added.

NAFTC ADDS PROPANE-SPECIFIC CURRICULUM

The National Alternative Fuels Training Consortium (NAFTC) of West Virginia University was represented at the Work Truck Show by interim director Micheal Smyth, who met with a number of propane industry stakeholders. “We have many projects going,” Smyth said. “Fleets are adopting, autogas product upfitters are making much more robust and stable systems, and early adopters are feeling much more confident in their autogas vehicles.”

Smyth told BPN that NAFTC is currently creating several training projects for the Propane Education & Research Council (PERC). “We are putting a propane autogas training program online for first responders,” Smyth added. “We are creating education on how the vehicle works and what they need to know when they respond to an accident. In addition, NAFTC is preparing an online version of Propane 101. This should allow for shortening of technical training from a three-day to a two-day class if students do the Propane 101 online and replace some ‘dry lecture’ with a more interesting approach.”

NAFTC is also producing videos for PERC on autogas facility maintenance, tank purging at the commissioning, and how propane acts in the transfer process.