Tuesday, November 8, 2016

Oregon’s Linn-Benton Community College (LBCC) has just completed another phase of its Advanced Transportation Technology Center (ATTC), which hosts programs that train technicians to install, maintain, and repair vehicles fueled by alternative energies such as propane.

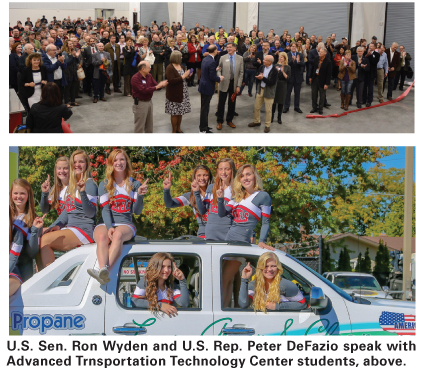

Nearly 300 people attended a ribbon-cutting ceremony in October marking the completion of the center’s second phase and the opening of the Innovation Center and Heavy Transportation building, a 37,000-sq-ft space that will be used to train technicians to work on heavy equipment. Among the guests were U.S. Sen. Ron Wyden and U.S. Rep. Peter DeFazio, Oregon lawmakers who have been strong supporters of Linn-Benton Community College’s alternative fuel training efforts.

The college’s Heavy Transportation Program covers all aspects of diesel, truck, and forestry equipment, in addition to training on alternative fuels like propane, CNG, and biodiesel. The facility joins a 35,000-sq-ft building next door that is home to the college’s automotive technology program, which also provides training on alternative fuels.

That previous $2.5-million inaugural phase involved the installation of a $200,000 dynamometer for the automotive technology program that tests vehicle performance before and after conversion to propane and other alternative energies. The “dyno” is one of only three in use west of the Mississippi River, with the others in California and Canada. The dyno measures emissions and power performance of vehicles and generates comparative data.

BPN has reported on how CoEnergy Propane (Albany and Redmond, Ore.) has served in a consulting capacity to ATTC, assisting the center in training technicians on propane autogas technology (BPN, April 2015, p. 56). It started when CoEnergy general manager Randy Camp heard LBCC president Greg Hamann make presentations on alternative fuels, but neglect to mention propane. After several conversations between Hamann and Camp, CoEnergy Propane became the college’s propane partner, and Camp helped the college organize training for its instructors on propane. And around the same time the company donated a 1991 Chevy Kodiak truck to the program.

In addition to propane, the center is involved in training technicians on CNG, biodiesel, electric, and hydrogen. Camp noted that propane is the “leading portion right now” at the center because of the ready infrastructure availability. This past June, LBCC appointed Camp to its board of education.

Some past important propane projects have taken place through the partnership. Working with CoEnergy and ATTC, the Benton County Sheriff’s Office in Albany, Ore. reported in September that it had finished converting its fleet to run on a bi-fuel propane/gasoline system, and that use of the system saved the agency nearly $24,000 in fuel costs in 2015. Converted vehicles included Ford Crown Victorias, Chevrolet Tahoes, a Ford Expedition, a Ford F-150 pickup, and a Ford inmate shuttle van. The selected vehicles were converted using an AGA Systems and American Alternative Fuel bi-fuel conversion system.

In August, CoEnergy presented a $6700 check to Benton County that represented the 50-cent/gal. federal rebate for vehicles fueled by propane autogas. The partnership also recently converted a vehicle for Benton County Dial-A-Bus.

Camp said he feels it is important to note that the school is designed to teach, and is not designed to be an actual conversion center. The center shows students how to do conversions in steps. As an example, while performing a conversion, students might learn the whole process of tank installation. After finishing the installation, the students might not do anything else with that particular vehicle. “We may take that vehicle from them and finish that job,” CoEnergy Propane’s general manager said. In another situation, the students might only install the fuel system.

Some students are CoEnergy Propane employees who attend LBCC in the morning, and go to the CoEnergy Propane facility in the afternoon to work on the same vehicle they worked on that morning. “They go back and forth and get college credits for that,” Camp said.

Propane-diesel technology will be one area of focus at the new heavy-equipment facility. Camp explained that many fleets need the added horsepower of propane-diesel technology, especially logging companies driving large trucks in mountainous areas. He stressed that propane-diesel technology is still in the testing phase, including on some CoEnergy trucks, but he says the technology has already resulted in cost savings for CoEnergy through reduced use of diesel.

Phase 3 of ATTC will be the opening of an Innovation Center, which will also be a training facility. Camp has worked extensively with Sen. Wyden, ranking member on the Senate Finance Committee and a member of the Energy and Natural Resources Committee, and DeFazio, ranking member of the House Transportation and Infrastructure Committee, whom he describes as steadfast supporters of the propane industry. The congressmen have expressed their hope to receive enough propane industry support to name the Innovation Center after the industry. Examples would be the National Propane Gas Association (NPGA) Innovation Center or the Propane Education & Research Council (PERC) Innovation Center.

“I’m not sure how it works, but we’ll be hitting up the people in D.C. to see if they will help us with the funds to help get our name on their building,” Camp said.

Camp added that Wyden and DeFazio support the concept that education does not have to result in a traditional four-year bachelor’s degree. Many ATTC students who have not yet graduated already have job offers. Camp has hired three graduates through the program and noted that it helps the industry with its shortage of qualified technicians. Oregon recently mandated a 10% reduction in greenhouse gases from transportation fuels. If fleets add propane vehicles, an adequate number of technicians must be available to work on them.

“At Linn-Benton, we’re trying put in place a means for students to get a degree or certificate and leave with a job in the career field they studied,” Camp concluded. —Daryl Lubinsky

Nearly 300 people attended a ribbon-cutting ceremony in October marking the completion of the center’s second phase and the opening of the Innovation Center and Heavy Transportation building, a 37,000-sq-ft space that will be used to train technicians to work on heavy equipment. Among the guests were U.S. Sen. Ron Wyden and U.S. Rep. Peter DeFazio, Oregon lawmakers who have been strong supporters of Linn-Benton Community College’s alternative fuel training efforts.

The college’s Heavy Transportation Program covers all aspects of diesel, truck, and forestry equipment, in addition to training on alternative fuels like propane, CNG, and biodiesel. The facility joins a 35,000-sq-ft building next door that is home to the college’s automotive technology program, which also provides training on alternative fuels.

That previous $2.5-million inaugural phase involved the installation of a $200,000 dynamometer for the automotive technology program that tests vehicle performance before and after conversion to propane and other alternative energies. The “dyno” is one of only three in use west of the Mississippi River, with the others in California and Canada. The dyno measures emissions and power performance of vehicles and generates comparative data.

BPN has reported on how CoEnergy Propane (Albany and Redmond, Ore.) has served in a consulting capacity to ATTC, assisting the center in training technicians on propane autogas technology (BPN, April 2015, p. 56). It started when CoEnergy general manager Randy Camp heard LBCC president Greg Hamann make presentations on alternative fuels, but neglect to mention propane. After several conversations between Hamann and Camp, CoEnergy Propane became the college’s propane partner, and Camp helped the college organize training for its instructors on propane. And around the same time the company donated a 1991 Chevy Kodiak truck to the program.

In addition to propane, the center is involved in training technicians on CNG, biodiesel, electric, and hydrogen. Camp noted that propane is the “leading portion right now” at the center because of the ready infrastructure availability. This past June, LBCC appointed Camp to its board of education.

Some past important propane projects have taken place through the partnership. Working with CoEnergy and ATTC, the Benton County Sheriff’s Office in Albany, Ore. reported in September that it had finished converting its fleet to run on a bi-fuel propane/gasoline system, and that use of the system saved the agency nearly $24,000 in fuel costs in 2015. Converted vehicles included Ford Crown Victorias, Chevrolet Tahoes, a Ford Expedition, a Ford F-150 pickup, and a Ford inmate shuttle van. The selected vehicles were converted using an AGA Systems and American Alternative Fuel bi-fuel conversion system.

In August, CoEnergy presented a $6700 check to Benton County that represented the 50-cent/gal. federal rebate for vehicles fueled by propane autogas. The partnership also recently converted a vehicle for Benton County Dial-A-Bus.

Camp said he feels it is important to note that the school is designed to teach, and is not designed to be an actual conversion center. The center shows students how to do conversions in steps. As an example, while performing a conversion, students might learn the whole process of tank installation. After finishing the installation, the students might not do anything else with that particular vehicle. “We may take that vehicle from them and finish that job,” CoEnergy Propane’s general manager said. In another situation, the students might only install the fuel system.

Some students are CoEnergy Propane employees who attend LBCC in the morning, and go to the CoEnergy Propane facility in the afternoon to work on the same vehicle they worked on that morning. “They go back and forth and get college credits for that,” Camp said.

Propane-diesel technology will be one area of focus at the new heavy-equipment facility. Camp explained that many fleets need the added horsepower of propane-diesel technology, especially logging companies driving large trucks in mountainous areas. He stressed that propane-diesel technology is still in the testing phase, including on some CoEnergy trucks, but he says the technology has already resulted in cost savings for CoEnergy through reduced use of diesel.

Phase 3 of ATTC will be the opening of an Innovation Center, which will also be a training facility. Camp has worked extensively with Sen. Wyden, ranking member on the Senate Finance Committee and a member of the Energy and Natural Resources Committee, and DeFazio, ranking member of the House Transportation and Infrastructure Committee, whom he describes as steadfast supporters of the propane industry. The congressmen have expressed their hope to receive enough propane industry support to name the Innovation Center after the industry. Examples would be the National Propane Gas Association (NPGA) Innovation Center or the Propane Education & Research Council (PERC) Innovation Center.

“I’m not sure how it works, but we’ll be hitting up the people in D.C. to see if they will help us with the funds to help get our name on their building,” Camp said.

Camp added that Wyden and DeFazio support the concept that education does not have to result in a traditional four-year bachelor’s degree. Many ATTC students who have not yet graduated already have job offers. Camp has hired three graduates through the program and noted that it helps the industry with its shortage of qualified technicians. Oregon recently mandated a 10% reduction in greenhouse gases from transportation fuels. If fleets add propane vehicles, an adequate number of technicians must be available to work on them.

“At Linn-Benton, we’re trying put in place a means for students to get a degree or certificate and leave with a job in the career field they studied,” Camp concluded. —Daryl Lubinsky