Low-carbon fuel sources will be critical for the United States to meet its ambitious climate targets. In August 2022, President Joe Biden signed the Inflation Reduction Act into law, which sets out new ambitions for the country to invest in infrastructure, technology and manufacturing to meet its commitment to reduce greenhouse gas emissions by 50% to 52% from 2005 levels by 2030. At a state level, we also see an increasing regulation in this space, with more than 50% of the U.S. population now living in a state with significant carbon emissions legislation.

Low-carbon fuel sources will be critical for the United States to meet its ambitious climate targets. In August 2022, President Joe Biden signed the Inflation Reduction Act into law, which sets out new ambitions for the country to invest in infrastructure, technology and manufacturing to meet its commitment to reduce greenhouse gas emissions by 50% to 52% from 2005 levels by 2030. At a state level, we also see an increasing regulation in this space, with more than 50% of the U.S. population now living in a state with significant carbon emissions legislation.

Cleaner energy sources like propane will be necessary to reduce emissions across the U.S., especially from high-carbon oil or coal usage. Propane is already the third-most widely used energy source for heating in the U.S., supporting 50 million homes and 1.1 million businesses. According to the Propane Education & Research Council, “Propane-fueled space and water heating contribute 50% and 46% fewer [greenhouse gas] emissions than electric alternatives, respectively,” as well as “12% fewer greenhouse gas emissions and 80% fewer NOx emissions compared with a heating oil furnace.” However, as we look to the future, there is an increase in need and demand for renewable fuels to reduce emissions further. Renewable propane is one of these important solutions — another is dimethyl ether (DME).

Renewable & Recycled Carbon DME

DME is chemically similar to LPG and has already been used extensively in the industrial sector and as an aerosol propellant. It is a gas at room temperature and atmospheric pressure but can be easily transported as a liquid in pressurised cylinders and tanks.

Renewable and recycled carbon DME can be made using a variety of feedstocks, such as waste or biomass. The fuel can help cut emissions by up to 85% for rural communities, reaching over 100% savings if manure or carbon capture is used. These feedstocks can then go through catalysis or gasification processes to produce the DME, with future pathways, such as “power-to-X” using CO2 and renewable hydrogen, on the horizon.

Since it is chemically similar to liquefied petroleum gas (LPG), it can be “dropped in” to existing LPG supply chains in a blended form. This provides immediate emissions reduction for the consumer and significantly contributes to propane’s de-fossilization. Global work is underway to implement this initial blend ratio, which would offer seamless solutions to propane customers — minimizing disruption and maximizing use of existing infrastructure.

DME can also be used on its own, an option perhaps for large industrial or commercial players who have strict environmental targets to meet and currently operate with oil. Either way, on its own or blended, DME provides an opportunity to grow the industry’s market further.

Growing DME Production

The interest in using and producing renewable and recycled carbon DME is growing. We see new players taking action to produce the molecule, DME-related projects getting support from national governments, and work underway to enable its rollout.

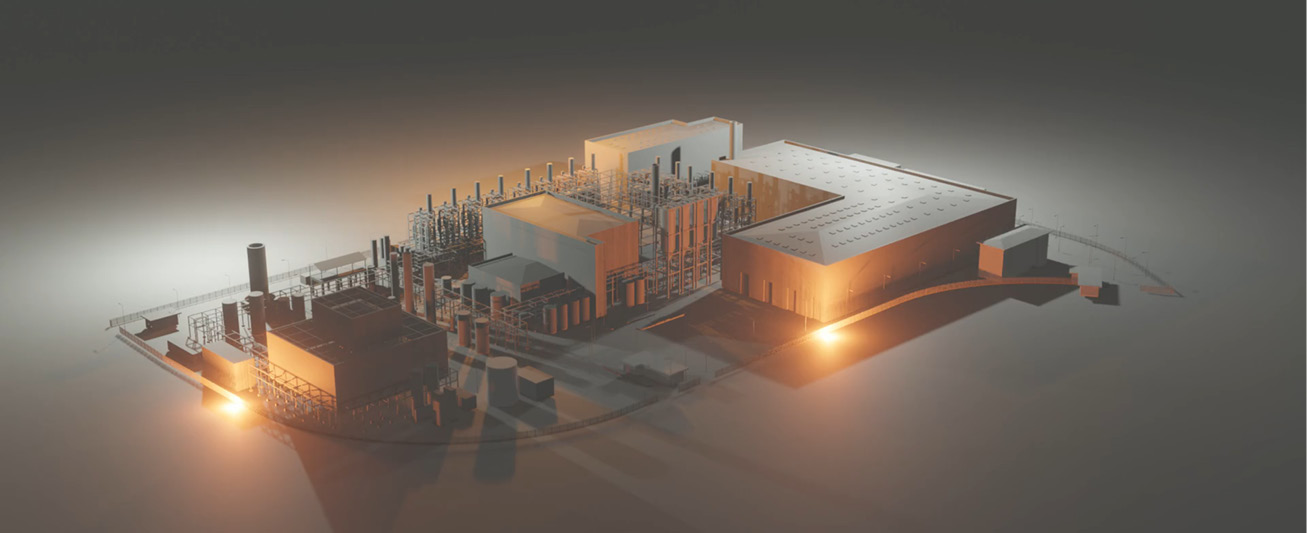

As part of this growing interest, Dimeta was established in February 2022 with the purpose of accelerating the production and use of DME. The organization is targeting the development of up to six production plants by 2027, with a capacity of up to 300,000 tonnes of sustainably made DME. The aggregate investment is expected to be up to $1 billion.

Dimeta is in the process of building its first production plant, which will be in operation in 2025. The project has seen the launch of a new joint venture between Dimeta and KEW Technology called “Circular Fuels,” which seeks to develop construction-ready DME production plants using KEW’s proprietary advanced gasification process. Approximately 220kt of waste will be converted into 50,000 tonnes of DME — the equivalent of 25% of the United Kingdom’s LPG domestic heating market. The construction will create 250 jobs, with 50 jobs for the local area once operational. Following the first plant in the U.K., subsequent plants are under development in Europe and the U.S.

Dimeta has also partnered with Canada-based company Enerkem, the first company in the world to produce renewable methanol and ethanol from nonrecyclable, noncompostable municipal solid waste at full commercial scale. This partnership will explore the opportunity for the development of renewable and recycled DME plants at a larger scale of circa 150,000 metric tonnes per annum in North America and Europe.

Waste to DME: Solving Problems to Create Solutions

By tapping into the latest technological advancements, Dimeta’s production plants will be able to produce versatile DME using waste, including both biogenic waste and nonrecyclable waste — for example, nonrecyclable plastics.

The total generation of municipal solid waste in the U.S. is 292.4 million tons, with 146.1 million tons of that going to landfills. Turning waste into fuels in this circular way makes “waste-to-DME” a much more sustainable use of a waste resource, helps prevent local pollution associated with landfills, and creates a low-carbon fuel that can power hard-to-electrify homes, businesses and industries that are off the gas grid.

Municipal waste can be taken from the local area around a DME production plant and used as a feedstock to produce the molecule. The resulting renewable and recycled carbon DME can then be used to provide energy in the region. Management of the feedstock supply chain and production of the new fuel can also create long-term local jobs.

While the goal globally is to reduce the amount of waste we produce over time, there will always be a considerable portion of unavoidable waste. Being able to use these feedstocks to create a fuel that provides a solution for off-grid energy helps to develop a more circular economy.

Reaching Our Targets

Decarbonization is not something that can happen overnight. However, as the U.S. raises its ambitions to significantly reduce emissions by the end of the decade, solutions will be needed that can deliver significant reductions. Propane is a critical solution for this transition, and renewable and recycled DME can help decarbonize the market further.

Working together with the propane market, DME can support the industry in its bid to provide a fair, affordable and cleaner future for homes and businesses in off-grid communities across the U.S.