Safety is the backbone of every propane and midstream operation. From the moment infrastructure is designed to the way facilities are maintained day to day, the decisions companies make directly affect employees, customers, assets and the surrounding communities. In an industry where compliance is not optional, the most successful operators go beyond regulatory requirements to create a culture of safety that supports resilience and long-term growth.

Advancements in construction methods, automation and operational practices are giving companies more tools than ever before to strengthen their safety performance. By prioritizing both people and infrastructure, propane and natural gas liquids (NGL) operations can reduce risks, improve efficiency and create environments where safety and productivity reinforce one another.

Why NGL Operations Safety Starts With Infrastructure

In propane and midstream NGL operations, safety is not only a regulatory requirement but also a critical foundation for protecting people, assets and surrounding communities. Effective safety practices also support operational reliability and long-term performance.

Risk Assessments Reduce Long-Term Costs

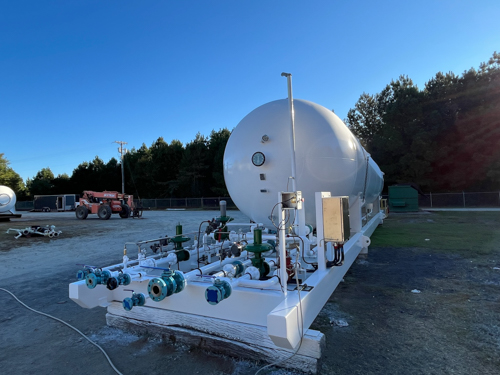

Safety considerations begin with infrastructure design. Facilities such as bulk storage plants, terminals and midstream transfer sites are exposed to unique risks during storage, transfer and distribution.

To address these challenges, systems are typically equipped with safeguards, such as pressure-relief configurations, emergency shutdown integration and optimized equipment layouts. Conducting early risk assessments and hazard analyses helps identify potential issues before construction begins, reducing redesign costs and mitigating long-term risks.

Modular Construction Safety Advantages

Modular construction has become an important driver of improved safety performance. Prefabricated and pretested propane and NGL systems are assembled in controlled environments and then transported to the field for installation. This approach minimizes on-site hazards, accelerates commissioning and ensures consistent quality across multiple facilities.

The Role of Automation

Automation further strengthens safety by reducing reliance on manual intervention. Integrated control systems enable rapid emergency shutdowns, continuous monitoring of critical system parameters and remote diagnostics. These capabilities help facilities meet safety standards established by organizations, such as the National Fire Protection Association, Department of Transportation and Occupational Safety and Health Administration. By automating routine monitoring and response functions, safety teams are better able to focus on prevention.

NGL Operations Safety Practices

The long-term safety of any facility depends on how it is operated and maintained. Standardized operating procedures, hands-on training and structured maintenance programs not only extend equipment life but also ensure regulatory compliance. Aligning infrastructure with well-trained personnel and established processes creates a comprehensive and sustainable safety framework.

Turning Safety Into Strength

When engineering design, modular systems, automation and operational training are combined, the result is reduced risk, improved uptime and safer facilities overall. For organizations involved in propane and midstream NGL operations, integrating these practices provides a pathway to confident, compliant and resilient operations — meeting today’s safety expectations while preparing for future growth.

Propane and midstream NGL facilities face unique safety challenges, but those challenges can be turned into opportunities with the right approach. By combining smart design, modular construction, advanced automation and a strong focus on training and standardized procedures, operators can establish a comprehensive framework that protects people and assets while ensuring full regulatory compliance.

Safety is not just a box to check — it is an investment in reliability, trust and long-term performance across the industry.