Wednesday, May 17, 2017

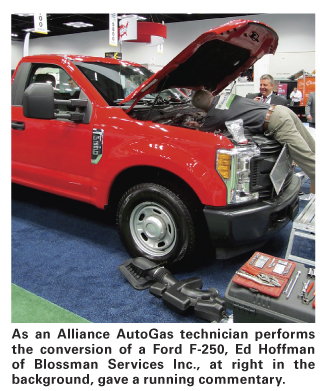

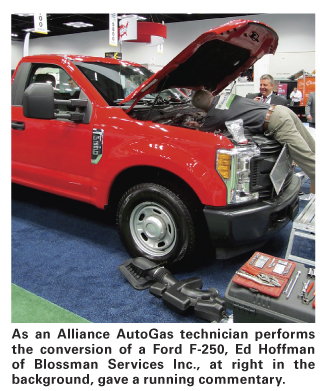

Propane continued to make headway as a commercial vehicle fuel, with the added bonus that it’s “green,” at the 2017 Work Truck Show/Green Truck Summit in Indianapolis in March 2017. Vehicle displays, a session on propane’s role in emissions reduction, and an Alliance AutoGas event at which conversion specialists once again performed a live upfit of a 2017 Ford F-250 to propane, drew interest from attendees. The techs completed the demonstration in 1:21.00, beating their F-150 conversion speed at last year’s Work Truck Show of 1:32:25 (BPN, April 2016, p.62), which Alliance described at the time as the fastest live propane autogas conversion.

Stacey Snyder, conversion specialist from Alliance AutoGas in Asheville, N.C., assisted Kevin Oglesby, conversion specialist from Alliance member Southern Alternatives LLC in Athens, Ga., in the installation of the Alliance AutoGas engineered conversion system.

Ed Hoffman, president of Blossman Services Inc. (Swannanoa, N.C.), manufacturer of record for Alliance AutoGas emissions certifications, served as the emcee for the Alliance upfit event. During the conversion, he provided a running commentary on just what the technicians were doing. As the process was in progress, Hoffman spoke with BPN and expanded on his comments, explaining that the best way to describe the techs’ work at the event is “to follow the fuel.”

“This is where we fill the vehicle,” Hoffman explained. “We’re going to fill the underbody tank, then the system will wait for the signal to be able to use propane. Propane will flow under its own pressure — no pumps, to the front of the vehicle. It’s actually a component that Stacey is handling right now, called a reducer. At that component, we’re going to heat the propane and turn it from a liquid into a vapor, then do what Stacey just did, which is install the component that will inject propane into the engine. The last piece is our wiring, the controller that’s built in to make sure it works properly. That’s it. That’s the whole system. We take the mystery out of it. Not a lot of stuff is being added here, not a lot of pieces, and not a lot of complexity to this.”

The Work Truck Show began with the Green Truck Summit. Keynote speaker Wilfried Achenbach, senior vice president of engineering and technology for Daimler Trucks North America, said the nation is on the path toward autonomous vehicles, “but it won’t come overnight. We will need vehicles communicating with other vehicles. We will need high-resolution GPS and better maps.”

The Green Truck Summit’s host, John Davis, host and creator of the long-time automotive series “Motor Week,” noted that at last year’s Work Truck Show, the country was in the middle of a period of collapsing oil prices. Then came the recent national election.

“Little did any of us know then that one year later not only are prices still at historic lows or near them, but that a new political broom would sweep into town and with it put in question many regulations that have guided alternative-fuel actions both big and small in recent years.”

Davis is optimistic about the future of alternative fuel vehicles, adding that with the commitment of Green Truck Summit and Work Truck Show attendees to a clean driving future, the U.S. could be on the verge of a more open environment for alternative fuels than ever. Ideally, government would no longer pick favorites and let the open market find the best fit for each need.

“Today, there are more viable options than ever to move toward…a future of zero-emission commercial vehicles,” Davis said. “This year’s Green Truck Summit will provide an international forum of thought leadership on…options and strategies to move toward the goal of zero-emission work trucks.”

Propane made a strong play at the Work Truck Show to get a seat at that table. While the Alliance AutoGas conversion event was a major highlight of the show for propane, various propane industry companies made their case for the outstanding reasons to choose propane autogas. One example was Freightliner Custom Chassis Corp. (FCCC; Gaffney, S.C.), which displayed a Freightliner S2G propane cab and chassis.

Bryan Henke, manager, product marketing, at FCCC, spoke with BPN about its efforts to make inroads into the food truck industry. He noted that his company has spoken to walk-in van company Morgan-Olson, which launched a food truck upfitting program at the Work Truck Show, about using the Freightliner MT-45 and MT-55 6.0L chassis. The chassis would serve the dual purpose of running the engine on propane as well as using the propane for cooking. The MT-45 and MT-55 chassis are long-time walk-in van chassis that are seen on trucks for package delivery companies such as UPS and FedEx. Other uses of the MT-45 and MT-55 chassis include demanding routes such as newspaper delivery, industrial laundry, tool trucks, and utility service.

“FCCC is looking to get into the food truck market this way,” said Mike Stark, product manager, commercial chassis, for FCCC. “We’ll go to a food truck company…and tell them they can run the vehicle on propane and also use it as a cooking fuel. It saves space and money.”

Kevin Erb of Ferguson Advertising, which represents FCCC, noted that FCCC’s work in the food truck area is in its infancy, but ideally the company would manufacture a simple mechanism through which the cooking tank could draw propane from the outside fuel tank. However, the mechanism would keep a separation between the fuel tank and cooking tank as opposed to pulling directly from the fuel tank. “So if you are cooking, and the truck is not running, you can shut off the fuel source and maintain a separation between the fuel source and cooking fuel at that time so you’re not just pulling directly from it.”

Stark added that FCCC is focusing on six applications for the S2G: propane bobtail; box truck; flat-bed truck; crane; beverage body; and “rollback wrecker,” a flat-bed tow truck.

He elaborated on FCCC’s update of its 24/7 service initiative in which drivers can speak to knowledgeable service representatives anytime they have a service issue with one of their vehicles. Those who answer the phone “are all tenured individuals who know the product. They’re graded on their performance in call-back time, hold time, and dropped calls. We talk every morning in our 8:30 a.m. production meeting to see if we met our goals for service.” He added that the hold time for FCCC’s (800) FTL-HELP line averages about 90 seconds. The 24/7 service includes an app that users can download.

“Training is a big deal for us,” Stark said. “When a truck comes in, we make sure the dealer is trained. A bad customer experience doesn’t help us with promoting the product.”

Tucker Perkins, COO for the Propane Education & Research Council (PERC), gave a presentation titled, “Propane Autogas: A Viable Economic Solution for Emissions Reduction.” He pointed out that propane autogas is doing well in the areas of economics and emissions.

During his talk, he displayed a graphic from PERC showing that propane’s greenhouse gas emission profile in light-duty vehicles is 14% better than gasoline, and that NOx emissions in light-duty vehicles are 57% better than diesel. For medium-duty vehicles, propane’s profile for greenhouse gas emissions is 27% better than gasoline and its NOx emissions profile is 31% better than gasoline and 18% better than diesel.

“I tend to say, a lot of diesel is pretty clean, but it’s clean because it has a very complex after-treatment,” Perkins explained. “Propane is clean because propane is inherently clean.”

Perkins provided a video interview with Bill Spraul, COO for the San Diego Metropolitan Transit System, who revealed the entity will soon have more than 70 propane buses in its fleet. “The vehicles perform almost exactly like our other technologies,” Spraul said.

Stuart Weidie, president of Alliance AutoGas and president and CEO of Blossman Gas, echoed Perkins’ enthusiasm about propane autogas and talked about the truck that Alliance used at its live conversion demonstration at last year’s Work Show. Following that event, the same vehicle took part in the Alliance AutoGas Clean Air Coast-to-Coast Ride, traveling 5300 miles from Kansas City, Kan., to Portland, Ore., then to Jacksonville, Fla. and finally Asheville, N.C.

Weidie told attendees that the truck from that ride has been in continuous use, serving an Alliance salesman, ever since last year’s event. “It made the coast-to-coast trip, then immediately went into service, and has been in service since then over the last year with no maintenance on it.”

He added, “Last year, the theme was, ‘We can do this quickly,’ and some people thought, ‘Well, there is something wrong with it if you did it that fast.’ What we want to demonstrate is when we do a plug-and-play system, the installation is reliable, but it’s durable and very little maintenance is required. That’s sort of the theme this year. We want to demonstrate the robust, reliable, and durable nature of our system and its installation, our aftermarket conversion.”

Hoffman of Blossman Services Inc. also had a message for propane marketers: They have no reason to buy a diesel vehicle. “This is available to every marketer in the country. We have special pricing for the industry. There are really no excuses. Use your own fuel.” —Daryl Lubinsky

Stacey Snyder, conversion specialist from Alliance AutoGas in Asheville, N.C., assisted Kevin Oglesby, conversion specialist from Alliance member Southern Alternatives LLC in Athens, Ga., in the installation of the Alliance AutoGas engineered conversion system.

Ed Hoffman, president of Blossman Services Inc. (Swannanoa, N.C.), manufacturer of record for Alliance AutoGas emissions certifications, served as the emcee for the Alliance upfit event. During the conversion, he provided a running commentary on just what the technicians were doing. As the process was in progress, Hoffman spoke with BPN and expanded on his comments, explaining that the best way to describe the techs’ work at the event is “to follow the fuel.”

“This is where we fill the vehicle,” Hoffman explained. “We’re going to fill the underbody tank, then the system will wait for the signal to be able to use propane. Propane will flow under its own pressure — no pumps, to the front of the vehicle. It’s actually a component that Stacey is handling right now, called a reducer. At that component, we’re going to heat the propane and turn it from a liquid into a vapor, then do what Stacey just did, which is install the component that will inject propane into the engine. The last piece is our wiring, the controller that’s built in to make sure it works properly. That’s it. That’s the whole system. We take the mystery out of it. Not a lot of stuff is being added here, not a lot of pieces, and not a lot of complexity to this.”

The Work Truck Show began with the Green Truck Summit. Keynote speaker Wilfried Achenbach, senior vice president of engineering and technology for Daimler Trucks North America, said the nation is on the path toward autonomous vehicles, “but it won’t come overnight. We will need vehicles communicating with other vehicles. We will need high-resolution GPS and better maps.”

The Green Truck Summit’s host, John Davis, host and creator of the long-time automotive series “Motor Week,” noted that at last year’s Work Truck Show, the country was in the middle of a period of collapsing oil prices. Then came the recent national election.

“Little did any of us know then that one year later not only are prices still at historic lows or near them, but that a new political broom would sweep into town and with it put in question many regulations that have guided alternative-fuel actions both big and small in recent years.”

Davis is optimistic about the future of alternative fuel vehicles, adding that with the commitment of Green Truck Summit and Work Truck Show attendees to a clean driving future, the U.S. could be on the verge of a more open environment for alternative fuels than ever. Ideally, government would no longer pick favorites and let the open market find the best fit for each need.

“Today, there are more viable options than ever to move toward…a future of zero-emission commercial vehicles,” Davis said. “This year’s Green Truck Summit will provide an international forum of thought leadership on…options and strategies to move toward the goal of zero-emission work trucks.”

Propane made a strong play at the Work Truck Show to get a seat at that table. While the Alliance AutoGas conversion event was a major highlight of the show for propane, various propane industry companies made their case for the outstanding reasons to choose propane autogas. One example was Freightliner Custom Chassis Corp. (FCCC; Gaffney, S.C.), which displayed a Freightliner S2G propane cab and chassis.

Bryan Henke, manager, product marketing, at FCCC, spoke with BPN about its efforts to make inroads into the food truck industry. He noted that his company has spoken to walk-in van company Morgan-Olson, which launched a food truck upfitting program at the Work Truck Show, about using the Freightliner MT-45 and MT-55 6.0L chassis. The chassis would serve the dual purpose of running the engine on propane as well as using the propane for cooking. The MT-45 and MT-55 chassis are long-time walk-in van chassis that are seen on trucks for package delivery companies such as UPS and FedEx. Other uses of the MT-45 and MT-55 chassis include demanding routes such as newspaper delivery, industrial laundry, tool trucks, and utility service.

“FCCC is looking to get into the food truck market this way,” said Mike Stark, product manager, commercial chassis, for FCCC. “We’ll go to a food truck company…and tell them they can run the vehicle on propane and also use it as a cooking fuel. It saves space and money.”

Kevin Erb of Ferguson Advertising, which represents FCCC, noted that FCCC’s work in the food truck area is in its infancy, but ideally the company would manufacture a simple mechanism through which the cooking tank could draw propane from the outside fuel tank. However, the mechanism would keep a separation between the fuel tank and cooking tank as opposed to pulling directly from the fuel tank. “So if you are cooking, and the truck is not running, you can shut off the fuel source and maintain a separation between the fuel source and cooking fuel at that time so you’re not just pulling directly from it.”

Stark added that FCCC is focusing on six applications for the S2G: propane bobtail; box truck; flat-bed truck; crane; beverage body; and “rollback wrecker,” a flat-bed tow truck.

He elaborated on FCCC’s update of its 24/7 service initiative in which drivers can speak to knowledgeable service representatives anytime they have a service issue with one of their vehicles. Those who answer the phone “are all tenured individuals who know the product. They’re graded on their performance in call-back time, hold time, and dropped calls. We talk every morning in our 8:30 a.m. production meeting to see if we met our goals for service.” He added that the hold time for FCCC’s (800) FTL-HELP line averages about 90 seconds. The 24/7 service includes an app that users can download.

“Training is a big deal for us,” Stark said. “When a truck comes in, we make sure the dealer is trained. A bad customer experience doesn’t help us with promoting the product.”

Tucker Perkins, COO for the Propane Education & Research Council (PERC), gave a presentation titled, “Propane Autogas: A Viable Economic Solution for Emissions Reduction.” He pointed out that propane autogas is doing well in the areas of economics and emissions.

During his talk, he displayed a graphic from PERC showing that propane’s greenhouse gas emission profile in light-duty vehicles is 14% better than gasoline, and that NOx emissions in light-duty vehicles are 57% better than diesel. For medium-duty vehicles, propane’s profile for greenhouse gas emissions is 27% better than gasoline and its NOx emissions profile is 31% better than gasoline and 18% better than diesel.

“I tend to say, a lot of diesel is pretty clean, but it’s clean because it has a very complex after-treatment,” Perkins explained. “Propane is clean because propane is inherently clean.”

Perkins provided a video interview with Bill Spraul, COO for the San Diego Metropolitan Transit System, who revealed the entity will soon have more than 70 propane buses in its fleet. “The vehicles perform almost exactly like our other technologies,” Spraul said.

Stuart Weidie, president of Alliance AutoGas and president and CEO of Blossman Gas, echoed Perkins’ enthusiasm about propane autogas and talked about the truck that Alliance used at its live conversion demonstration at last year’s Work Show. Following that event, the same vehicle took part in the Alliance AutoGas Clean Air Coast-to-Coast Ride, traveling 5300 miles from Kansas City, Kan., to Portland, Ore., then to Jacksonville, Fla. and finally Asheville, N.C.

Weidie told attendees that the truck from that ride has been in continuous use, serving an Alliance salesman, ever since last year’s event. “It made the coast-to-coast trip, then immediately went into service, and has been in service since then over the last year with no maintenance on it.”

He added, “Last year, the theme was, ‘We can do this quickly,’ and some people thought, ‘Well, there is something wrong with it if you did it that fast.’ What we want to demonstrate is when we do a plug-and-play system, the installation is reliable, but it’s durable and very little maintenance is required. That’s sort of the theme this year. We want to demonstrate the robust, reliable, and durable nature of our system and its installation, our aftermarket conversion.”

Hoffman of Blossman Services Inc. also had a message for propane marketers: They have no reason to buy a diesel vehicle. “This is available to every marketer in the country. We have special pricing for the industry. There are really no excuses. Use your own fuel.” —Daryl Lubinsky