Propane fueling hose reels make life significantly easier for operating on the go. Propane and fuel delivery is no small task, and the need for reels is at an all-time high to enhance organization and improve efficiency. Especially for the liquefied petroleum (LP) gas fueling industry, it is absolutely crucial these reels remain in peak condition to reduce downtime and avoid unnecessary hiccups.

Purpose-Built for LP Gas

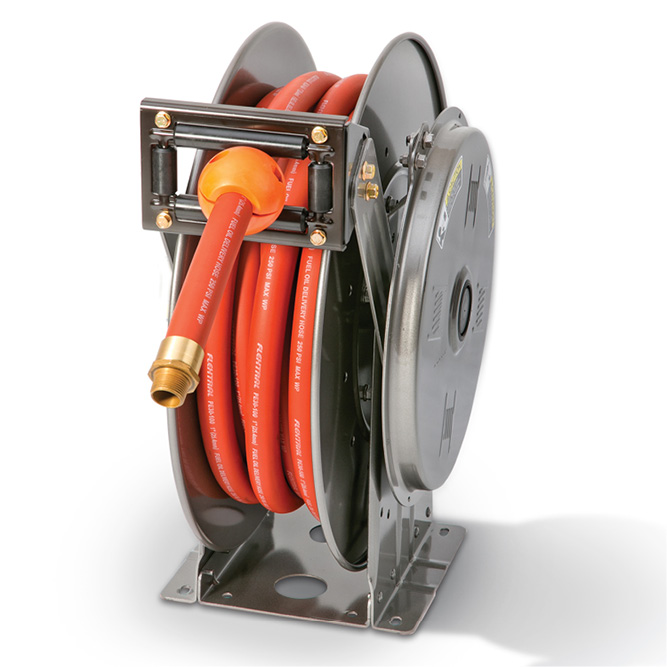

Customization options are available to meet every owner’s specific needs and requirements. These customizations can include various delivery truck mounting options, motor positions, different rewind mechanisms, temperature and pressure ratings, a range of hose lengths and widths, hose inlet and outlet configurations, reel dimensions and various accessories to enhance functionality for the task at hand.

Built stronger and more robust than ever, refueling reels are designed to handle high flow rates, high pressures and a wide range of temperatures. These reels offer great convenience, making it easy to deploy and retract the hose as needed while providing quick and efficient access.

Propane Fueling Hose Reels Designed to Last

To withstand extreme environments, fueling hose reels are built from durable materials, including aluminum and stainless steel. These materials offer superior protection against corrosion and contamination, oftentimes outlasting the propane trucks they are used on.

Manual rewind can slow workers down, which is why having power rewind capabilities is ideal. These components are heavy-duty and can handle the constant stress of rewinding and unwinding, ensuring fuel can be dispensed swiftly and proficiently.

Secure the Reels for Your Safety

LP gas and fueling is an essential process that requires careful attention to safety protocols to confirm efficient and secure operations. Reels aid in organizing long lengths of hose, minimizing the risk of tripping hazards and fuel spills. Fueling systems frequently possess features such as automatic shut-off valves to prevent overflows and other dangers. Reels can be equipped with optional chain guards, and various brake-and-lock features are standard to reduce incidents.

Operators require consistent, reliable control over the hose in order to keep up with demands. Pivoting hose guides are hose reel attachments that aid workers in unwinding and rewinding hoses more efficiently and safely. These guides help to pull the hose away from sharp corners and rough edges, preventing risks to operators and potential hose damage.

Tightness leads to safety, and users should inspect their reels regularly. If any components appear to be loose, make sure they are tightened and mechanically sound. When components are not properly fastened, parts can loosen and lead to a serious safety hazard.

It is important to double-check and ensure that the electrical connections on reel motors meet specifications. Motor chains should be adequately greased and in working order.

Monthly Maintenance Checks on Propane Fueling Hose Reels

Crews need equipment to work as hard as they do. Performing routine maintenance on hose and cable reels is key to keeping equipment in top working condition. Reels are bound to experience wear and tear over time, especially in refueling and propane applications. It is recommended to inspect them on a monthly basis due to the essential components involved.

Frequent use and harsh conditions can lead to reel malfunctions. It is critical to periodically inspect the state of the reel, and more often in the colder winter months of peak propane season. Salt, mud and sand are likely to accumulate on moving parts during this time of year, so it is crucial to regularly remove debris. Wind, rain and dust are also other factors to keep in mind throughout the year.

By consistently examining reel frames, discs, fluid paths, motors and swivel joints for damage, workers can focus more on the job rather than worrying about equipment mishaps.

Regular use makes inspecting and maintaining hose reels easy and convenient. Ensuring reels are in good working condition allows for safe and proper refueling options. To preserve quality performance and longevity, it is important to follow all the manufacturer’s instructions on proper reel and reel accessory maintenance.

Choosing the correct reel improves refueling operations by improving the ability to withstand harsh conditions, enhancing safety for workers and crews, and simplifying upkeep. Do your homework to find the right reel to take your business to the next level.