They accurately track fuel usage. They synchronize processes. They simplify delivery planning. They reduce extra stops and fuel runouts. They give the customer peace of mind. When used effectively, tank monitors solve multiple issues that have plagued propane suppliers for years. They can also have their downsides — installing and implementing a tank monitoring program across a wide berth of customers involves strategic planning and investment. And, as with any technology, issues during installation and deriving from long-term use and exposure to the elements will inevitably occur.

To mitigate these challenges, attention to detail at every point in the manufacturing process is paramount — from raw parts and supply chain management all the way to installation and use on the customer’s tank. Have you ever wondered how the product is made? BPN had the opportunity to visit Otodata’s offices and production facility in Montreal, Québec, Canada, earlier this fall to get an inside look at the manufacturing process of its tank monitors.

To recognize maximum profits and maintain a high standard of quality, every single step of the manufacturing process is focused on efficiency. By bringing almost every part of the tank monitor production in house — from the research and development department creating new versions of the product to the finishing and packaging of the finished monitors — the team can better control process challenges and mitigate the number of defective components that make their way to the end user.

The manufacturing process of the company’s tank monitors starts at ground zero: the warehouse on-site where raw materials are stored. The company uses another third-party warehouse to store some supply, but the majority of the product needed is held on-site. From the warehouse, the first step in the process is production of circuit boards via rapid prototyping.

Cofounders Andre Boulay (president of Otodata) and Jason Gallovich (executive vice president) also own a company called Tag Tracking, a solutions provider for vehicle theft prevention. The robotics technology the team invested in produces circuit boards for both these tracking devices and tank monitors.

Currently, a team of seven produces approximately 3,000 boards per day using automation technology through a Panasonic NPM X — welding and robotic equipment that allows the team to build out a model for the machine to use to replicate the same type of circuit board with almost perfect precision and accuracy. With the team running the machine 20 to 21 days a month, the output today is around 60,000 circuit boards per month. Quality control runs in tandem with the automation of the boards. The quality control team samples roughly 20% of the finished boards for imperfections.

From here, finished boards that meet the quality standards move to assembly, which takes place in a building a short walk away. If the circuit board is the brain of the tank monitor, the assembly process is paramount in building a body (housing) that can protect the technology within from years of use and to withstand the elements.

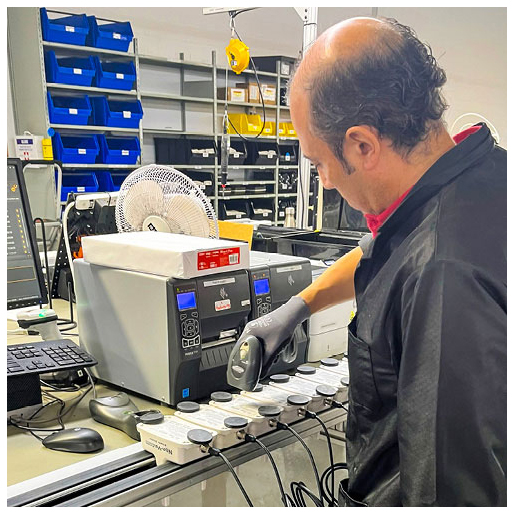

The team has adopted a binning and auto-replenishment system that allows for accurate and organized tracking of materials coming into the assembly process. Parts are color-coded by where they are needed in the assembly process and are tracked using the company’s enterprise resource management system to ensure they are always available where and when they are needed at assembly.

Full assembly of the tank monitors is done through assembly line automation and qualified assembly technicians. Team members take the completed circuit boards and attach each board to the bottom of the housing and seal it in a two-part encapsulation compound before attaching the rest of the parts, which include an external connector, Hall Effect sensor cable and mounting hardware, before closing up the housing and sending the fully assembled monitor to scanning and packaging.

Each monitor is scanned into the system and all of the units’ capabilities are tested before being packaged up and sent to the customer. The housing used for the monitors is not produced at the facility, but the company does label — whether branded with the company’s marketing or white-labeled for a specific customer — on-site. This process is done prior to the final assembly of the hardware.

All told, a manufacturing team of 60 runs two shifts daily to produce approximately 15,000 monitors per week. New generations of the tank monitors are designed at the facility by the company’s R&D team before being assembled and going through rigorous tests. Defective monitors are sent back to the facility for more rounds of testing and research.

This focus on testing is twofold — the fewer flawed units that make it out the door, the better, and all defective units that come back to the facility provide an opportunity to research and improve both current and future iterations of the product.

Stay Tuned for Part 2

Watch for part two of this series in print and online this winter, which will explore lessons learned by the Otodata team for more efficient tank monitor use, important elements for comprehensive technician training and how you can better address common customer pain points.