When setting or removing a tank, there are situations where a general-use dolly or hand truck is not enough and a crane truck is too much. For those times, what the propane marketer needs is a tool that’s somewhere in between, such as a purpose-built tank mover.

Three manufacturers who provide tank dollies, trailers, and other movers to the propane industry shared with BPN some circumstances where one of these units may be the best tool for the job.

The Challenge

It’s the busy season for tank setting and all your boom trucks have a full schedule. There are more tanks to set than the fleet can handle, but you don’t want to invest in another boom truck.

It’s the busy season for tank setting and all your boom trucks have a full schedule. There are more tanks to set than the fleet can handle, but you don’t want to invest in another boom truck.

The Solution

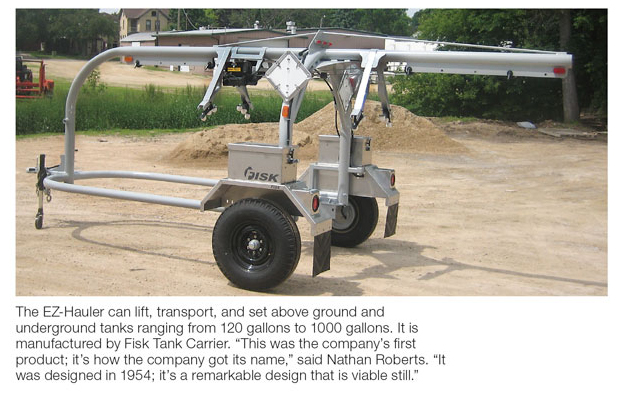

A tank trailer is pulled behind a pickup truck and can move tanks ranging from 120-gal. to 1000-gal. in size. Best of all, it costs less than $13,000. “What’s nice about a tank trailer is, you don’t have the overhead cost of a boom truck,” said Nathan Roberts, president of Fisk Tank Carrier (Columbus, Wis.). “You need only a single operator with a pickup and the trailer. You can add another tank setter for under $13,000. The marketer won’t mind that sitting around in the off season, whereas you need to use a boom truck year-round to get the return on investment. A tank trailer is a niche item for economy.”

The Challenge

The customer wants a tank placed out of sight, far away from a paved road or driveway. Or, you need to remove a tank that has been in sitting in a customer’s yard for 20 years and is now surrounded by a fence, a pool, shrubs, or other obstacles that make the tank hard to get to. In either case, a crane truck may not be able to get there, and using a winch to drag the tank will tear up the customer’s lawn and may damage the tank, equipment, or paint.

The customer wants a tank placed out of sight, far away from a paved road or driveway. Or, you need to remove a tank that has been in sitting in a customer’s yard for 20 years and is now surrounded by a fence, a pool, shrubs, or other obstacles that make the tank hard to get to. In either case, a crane truck may not be able to get there, and using a winch to drag the tank will tear up the customer’s lawn and may damage the tank, equipment, or paint.

The Solution

Purpose-built propane tank dollies are available in a choice of manual or motorized and in different configurations for horizontal or vertical tanks in sizes ranging from 100-gal. to 1000-gal. “In situations like these, using a crane truck could cost as much as the value of the tank, and manhandling the tank into position takes multiple guys,” said Jim Renaldo, president of Renaldo Sales & Service (North Collins, N.Y.). “With a dolly, one guy can put a tank where the customer wants it or take a tank out.”

The Challenge

The propane industry’s workforce is aging; hiring and retaining skilled employees is a challenge; the costs of trucks and employees are rising; and the cost of workers’ comp is going up too.

The Solution

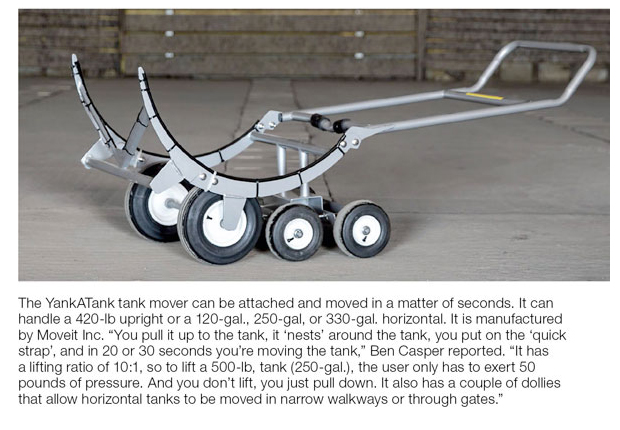

Using one of these purpose-built tank movers can make the job of setting, removing, or transporting tanks easier, faster, and safer. “A lot of propane managers tell me their workman’s comp claims are reduced because people aren’t pinching their fingers or straining their back,” Ben Casper, president of Moveit Inc. (Mesa, Wash.), reported. “Plus, these tools allow one guy to do the work of three or four guys. Marketers used to have to send a team to set a tank somewhere a truck can’t get to.”

These are just three of the circumstances in which a tank mover is the best tool for the job. Several different units are available with different capabilities and in a range of prices.

“I’ve never had to spend a minute educating propane marketers about this equipment,” Casper said. “Once they see a picture of it, they understand it. They either buy it or just keep doing what they’re doing.”

“I’ve never had to spend a minute educating propane marketers about this equipment,” Casper said. “Once they see a picture of it, they understand it. They either buy it or just keep doing what they’re doing.”

“Save time, energy, and expense,” Renaldo said. “Get yourself a dolly, even if it’s manual, as long as it’s specific to tanks. Don’t send a guy with just a two-wheel cart from a big-box store. We’re dealing with hazardous materials, your customers’ yards, and your employees’ backs. Get the right tool for the job.”

“Each of these tools has its own place in the market,” Roberts concluded. “Also, they don’t have a shelf life; they last and last. A lot of people look at a tank trailer as a thing of the past, but there are lot of modern reasons to have one.”