Tuesday, March 14, 2017

Propane truck builders have felt the pain of the warmer-than-average winter in many areas of the country, beginning with the winter of 2015-2016 and continuing into 2017.

“It’s still a little slow. All of the truck builders I’ve talked to said it was a down year,” said Rob Vandemark, who runs the truck division for Industrial Propane Service Inc. (Byron, Mich.). Speaking to BPN in early February 2017, he added, “It’s still slow taking off this year. I think marketers are hanging on to see what happens with politics, the presidential election, and what [President Trump] is going to do. So we’re optimistic as far as sales.”

Roger Smith of Kurtz Truck Equipment (Marathon, N.Y.) agreed with Vandemark about the warm winter’s effect on truck sales. “The business environment this year is terrible because of the lack of winter last year,” he commented. “We started getting quiet in December, and now it’s real quiet. Business is off probably 35%. We’re shifting our mechanics around doing more repair work and less new builds. Probably the biggest trend right now is there is no trend because nobody is buying trucks.”

Because the mild weather has caused a decline in business for propane marketers, they are spending more to repair equipment that they probably shouldn’t, Smith noted. After a slow winter, many marketers can’t afford to buy new trucks, so patching up old ones instead is their only choice. “Slow winters bring a lot of headaches, not just for me but also the retail guys, because they’re running that older equipment longer and longer,” Smith added.

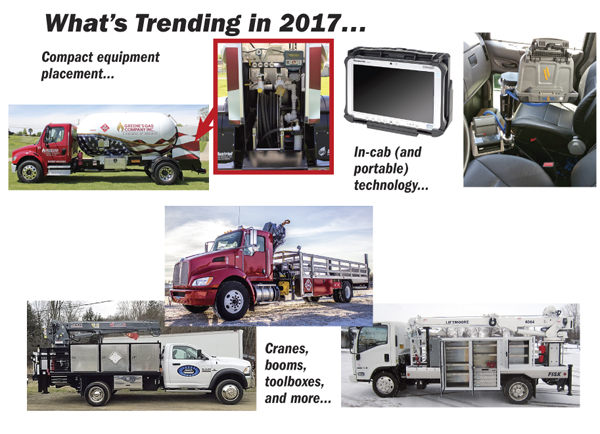

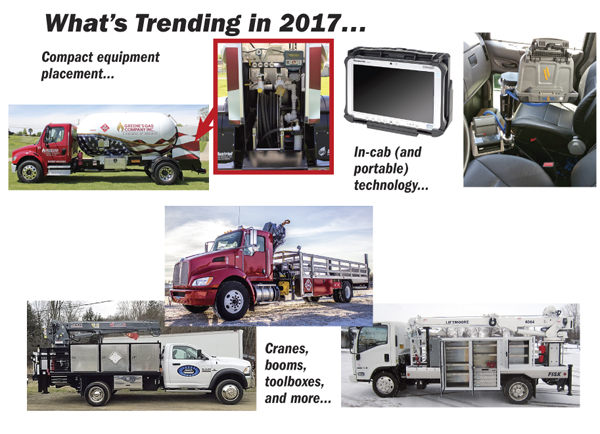

The news is not all bad, of course. Smith has seen an increase in crane truck orders, “like they’re going out of style.” Marketers are spending more money on hydraulic-operated crane trucks. In the past, Kurtz sold an average of about five hydraulic cranes per year, but the company received 10 orders in the first month of this year alone. The company’s customers have historically bought the less-expensive electric-over-hydraulic cranes.

“But now they’re shifting to the full-hydraulic cranes, because they’re realizing that electric-over-hydraulics just don’t hold up in our industry, and by going to the more expensive, more reliable, fully hydraulic crane, they will outlive two or three chassis,” Smith noted. Nathan Roberts of Fisk Tank Carrier (Columbus, Wisc.) is seeing an increase in boom truck sales. The reason? “I think people are changing to a one-man operation,” Roberts said. Marketers want installation and service to take place with one technician and one truck. The truck is becoming a warehouse. “People are setting them up and restocking them on a daily basis, keeping the jobs very efficient.” Customers of H&H Sales Co. (Huntertown, Ind.) have been purchasing more crane/service trucks with 14-ft-long bodies with 7000-lb capacity cranes to accommodate the transporting of 1000-gal. tanks with less overhang than on a 12-ft-long body, said H&H CEO John Hawkins.

More encouraging news: Ed Hoffman, president of Blossman Services (Ocean Springs, Miss.), said more propane marketers are expressing interest in running their fleets on autogas. “Our sales of the Ford F-Series trucks to the industry are way up,” Hoffman stated. “We see great adoption in tank-set trucks, service trucks, and bobtails. I’m excited about the adoption in the industry. The interest is there, which is great.”

Roush CleanTech (Livonia, Mich.) confirmed that its Ford F-750 bobtail orders are on the rise. Todd Mouw, vice president of sales and marketing for Roush CleanTech, heard in the early days of the F-750 bobtail development that few would buy the truck if it didn’t have air brakes. The product uses hydraulic brakes. “Now we’re seeing that trend go the other way. Propane companies are buying that truck for bobtails and cylinder exchange, which is good news,” Mouw stated, adding that the company has also seen an increase in demand for its medium-duty truck. Nestlé, which has ordered several hundred Roush CleanTech trucks for water-delivery applications, is one example. Mike Pitts, vice president of sales for Mississippi Tank (Hattiesburg, Miss.), pointed out that although his company is building more diesel-fueled trucks than propane models, “We would like as an industry to see that change. It depends on how well the technology holds up. More technology exists now. Three or four years ago, we had nothing that was truly a propane truck. Now we do have options out there.” Hawkins of H&H noted that “gasoline/propane power seems to be more active on new 2017-model-year Ford chassis than diesel engine power. We still have a few that will order diesel engines if they are in a multi-fuel-type business.”

Even though business is off overall, the products that are being sold continue to improve, becoming more durable and fuel efficient. The industry continues to see more customization of trucks to fit users’ specific needs, and use of the bobtail as more of a multi-use vehicle rather than simply a delivery vehicle.

Niche Trucks, Customization

Customers continue to be more involved in the design of the work trucks. They want the vehicles designed around the exact way they work.

“We’re a niche market, and now it’s starting to get to niche trucks that are inside that niche market,” said Roberts of Fisk Tank Carrier. Boom trucks are customized for the propane market, but inside that niche market, companies are ordering trucks pinpointed to another niche market. In this case, it is a truck with the primary task of delivering propane for temporary heat use. Propane marketers use these trucks to deliver tanks and propane to contractors for projects during the winter. Construction sites need heat in Roberts’ area of Wisconsin during a four- to five-month period.

Fisk recently sold a truck to a customer who needed it to be very precise for maneuverability in an extremely dense housing area of New England. “We’re seeing people are wanting what they want,” Roberts said, noting that efficiency with the right options is more valuable to customers now than low price. The truck is less of a commodity market item than it was even a couple years ago. “It’s more of a tailor-made-type situation.” Roberts adds that Fisk has seen great growth in the tank-carrier market segment. “We’ve literally had a backlog for a year and a half now.”

Vandemark of Industrial Propane Service noted his company’s Clear Vision Enclosure bobtail product (above) is a good example of customization. To provide greater visibility to the driver and to protect components from damage, the truck builders took all of the components—including the meter, hose reel, and piping—and “sucked it in and put it between the framerails of the chassis.”

The Bobtail: Different Uses

Propane marketers are looking for the bobtail to be available for various uses such as on-site cylinder filling, rather than just as a delivery vehicle, Vandemark noted. That particular use puts some strain on the normal delivery truck because the truck is built to pump 60 gpm, while cylinder filling only allows 6 gpm. “But they do it, and sometimes they plumb them a little differently so it’s less stress on the truck,” he noted. “It’s not a big thing, but we do see it and get asked about it.”

Customers of Westmor Industries (Morris, Minn.) have also asked for a bobtail that can fill cylinders. “We are looking at developing ideas for making the bobtail more of a multi-use vehicle,” said Milt Swenson, truck and trailer division sales manager for Westmor. “So we try to design systems that will allow the bobtail to do several different things rather than just fill domestic tanks or commercial tanks. We’re trying to make it more versatile.”

Marketers have told Westmor that they want products to make it easier to move propane back into the bobtail. The company is working on incorporating an evacuation-line system in the trucks to allow that. It will help improve efficiency and productivity for customers because they won’t have to use a different truck for the task. “And of course if you incorporate all that into one truck, it’s a lot less expensive than having to buy two or three vehicles to do the same jobs,” Swenson stated.

S2G Service

Kurtz’s Smith noted that in addition to the bobtail driver shortage that much of the industry is experiencing, a shortage of mechanics who can fix propane trucks is also a serious problem. When marketers who buy the Freightliner Custom Chassis Corp (FCCC) S2G propane-fueled bobtail need service on the vehicle, the Freightliner service people are not always as knowledgeable as they should be about the propane-fueled product, he added.

FCCC is taking steps to address that issue. Mike Stark, product manager, commercial chassis, for Freightliner, noted that S2G users often didn’t know whether to contact FCCC, Powertrain Integration, or CleanFUEL USA with service-related concerns. The entire service warranty process will now go directly through FCCC.

Dealer training is another area that FCCC is working to improve. The company has implemented a full-time training team with representatives from FCCC, Powertrain Integration, and CleanFUEL USA that will travel to train FCCC dealers on servicing the S2G and Thomas Built school buses.

“We want to be sure that 24/7, 365 days, you can call our call center and get an FCCC rep, not somebody who is maintaining phones but an actual rep who has technical expertise on the product,” Stark said. “We’re going to transition all the S2G product [questions] into our call center, which should alleviate a lot of questions and confusion for our customers.”

FCCC is also seeking to offer new options for the S2G, such as a new transmission and different power take-off (PTO), and wheelbase options. The company is also working on gearing the products to different vocations that typically use gasoline or diesel, and Stark noted FCCC is aiming toward offering new applications in the areas of beverage bodies and emergency vehicles. As an example, he noted that the company is in the early stages of working on switching from the S2G’s 2500 Allison transmission to an Allison 3000 series for an emergency vehicle application.

Stark also described the company’s increased emphasis on propane-specific sales training, including a 2016 national “road show.” In the fourth quarter of 2016, the company visited Freightliner dealers in Chicago, Charlotte, Boston, and Las Vegas, training the dealers on servicing the S2G. “At the end, we had dealers excited about the product, to take it on as a normal product within their portfolio and were excited to have it at their dealerships.”

Bigger (and Smaller) Tanks; Lightweighting

Lin’s Propane Trucks (Dighton, Mass.) has been building more bobtails with 5000-gal. barrels over the past couple of years. Scott Swensen, sales representative for Lin’s, noted that propane industry representatives in the past thought tandem-axle bobtails that can hold these larger tanks would “tear up driveways,” but that has not been the case.

“It’s kind of a change in mindset,” Swensen said. “A lot of places where there’s no trash pickup, they‘ve got dumpster guys going into these driveways all the time. They don’t have any issues. Most people are finding it works well for them. We’re moving a lot more of those.” He added that propane delivery drivers who used to load their 3499-gal. bobtails twice daily are now working more efficiently with the larger barrels.

Arch Hudelson, special projects director at Meeder Ransome (Fresno, Calif.), has noticed a trend for vessels with larger carrying capacity, “and the 3200-gallon WC vessels now greatly outnumber the small vessels in our production output. We are also viewing resurgence in requests for ‘jumbo’ bobtails with vessel sizes in the 4500-gallon to 5500-gallon range. These are typically designed as part of a three-axle straight truck or a single-axle ‘semi-trailer’ combination.” He is also seeing a trend of higher horsepower, “making these vehicles even more user-friendly in rugged terrain and heavily loaded situations.”

Smith at Kurtz is on the same page, noting that for the few trucks he is selling in the current challenging environment, “anything smaller than that 3499-gallon tank is pretty much obsolete.” His company is working on tandem bobtails with 4500- to 5500-gal. tanks, and even a couple of tri-axle 6000-gal. tanks. He explained that a tri-axle features two rear axles with an air-operated lift axle. “Tri-axle is a limited market. We have sold a few of them, but we’re seeing more and more tandems.” He added that in New York, the larger bobtail means higher sales and excise taxes. “That’s why people are hesitant to buy tandems, but more of them are saying that even with the ridiculous amount of taxes, it’s worth having.” In addition, with companies focusing more on driver productivity, they are looking to buy bigger trucks to keep the drivers on the road longer and delivering more gallons. He noted a disparity in wages among drivers in different areas of the country, which affects the choice of truck size. He heard that one company in Florida pays its drivers $14 per hour, while in his state of New York, he knows of a marketer paying $24. “It used to be that [the dealer] didn’t care what size truck they had because they would just run back, get another load, and go out and deliver. But if a company is delivering in an average 50- to 75-mile radius, if a driver is running back to get a second load, they’re losing an hour or two every time that truck goes empty.”

Pitts of Mississippi Tank is seeing few tanks below 2800 to 3000 gallons, and he pointed out the tanks get larger in the northern part of the country. The company is building 5000- to 6000-gal. tanks primarily for the major marketers’ northern state operations with large commercial accounts such as chicken or turkey houses or grain drying operations.

Several truck builders alluded to increasing truck sizes, but Swensen of Lin’s is also getting more requests for minis, and he mentioned a Ford F-550 with a 1200- or 1000-gal. barrel as an example. The truck can go almost anywhere, he noted, adding that weekend deliveries are a common use of the vehicles. “If you have an out-of-gas call, the tech can go there, do a leak check, and fill the tank at the same time.” Marketers are also using minis for cell tower accounts or rural camp areas. Lin’s previously built maybe one mini per year, but the company received more mini orders last year and has done about four or five so far this year.

Tim Schweppe, general manager of the propane division for Arrow Tank (Minneapolis), is seeing a focus on simplified troubleshooting and repair, “to get trucks pumping with all the new technology these days.” Marketers also continue to explore the option of using lightweight quenched and tempered (QT) vessels to further maximize bobtail payload. The increased payload comes with a significant cost upfront and with additional retest requirements, so companies must evaluate their application and decide whether the return on investment is sensible, Schweppe added. “Looking at single-axles, a 3499 vs. 3700 is more difficult to pencil out for a mere 171 gallons, but the tandem-axle vessels in excess of 5000 gallons make a guy scratch his head. Considering suitability for use on an equivalent chassis and the added capacity is what makes it more attractive. QT tanks are nothing new to Arrow as we manufacture everything onsite, including a state-of-the-art 110-ft PWHT (post weld heat treatment) oven needed to stress-relieve the material as part of the fabrication process.”

“Weight savings is a huge aspect of what everyone is doing,” said Roberts of Fisk. “You can see even Ford changing its body to aluminum. People are really trying to save weight. It’s cost savings for operational expenses for running the truck down the road, but they’re able to carry more payload, also. I think that’s becoming more the standard than it used to be.”

Driver Shortage: Creature Comforts

Swenson of Westmor addressed the driver shortage that is affecting the propane industry and others. “It’s almost like the days of a guy choosing a lifetime career delivering propane and refined fuels has come to an end. It’s hard to keep them when they have other opportunities.” He noted that propane truck builders are working on products with creature comforts to make truck driving a more attractive career option. He said his company’s Ergo-Load system features fill lines that are lower than those in conventional bobtails so drivers don’t have to lift the fill lines so high.

Meeder Ransome has fielded more requests from propane dealers for multi-point filling options when ordering new bobtails. Rather than choosing a rear-fill or a side-fill, they are asking for both. Hudelson added, “They explain the reason for such a configuration is flexibility in loading because they’re using multiple refueling sites within their operational area, and different fuel storage sites may favor opposite fill configurations.” Also, dealers are adding “driver-controlled” rear differential options for better control in wintry conditions.

Smart Bobtails, Troubleshooting

With all the new technology in the smart bobtails it builds, Arrow Tank is focusing on systematic design to simplify the troubleshooting and repair process. Schweppe noted that about 20 years ago, pumping issues were mechanical by nature and easily detected. “Fast forward to today, and the game has completely changed. We are using air and electronics to control a wide variety of components essential to the operation of the bobtail. The introduction of this technology has made the delivery process safer and more efficient, but [it] also has its challenges.”

Bobtails see their heaviest use during the harshest weather conditions, which Schweppe explained can be tough on some components. The components of today are robust and reliable, but they will only last so many cycles before they reach the end of their service life and fail. “Extremely cold temperatures expose the vulnerability of a component that is reaching the end of its service life. When the phone starts ringing off the hook, we know the temperature dropped around or below 0°F in this neck of the woods, and the troubleshooting process begins.”

It’s not a matter of if a component will fail, but when, Schweppe said. “Bobtails must be engineered to facilitate the troubleshooting process and procedures in place to handle that call from your customer. The bobtail operator reaches out to you as a lifeline expecting that you can make everything happy again. We need to make this happen quickly and with the least amount of pain and frustration due to an already compromised situation. When the call comes in, we picture ourselves in their shoes walking around the truck inspecting each element, and the design of our bobtails is systematic to make this easier.”

Schweppe added that Arrow has worked with its vendors to change the designs of products to be more “plug and play”-friendly to help facilitate repairs and the troubleshooting process. “Such changes come with an extra cost upfront, but it is invaluable when a compromised situation arises.”

Electronics, New Gadgets, Safety Features

Wayne Terpstra of Utility 1 Source (Kansas City, Mo.), which builds utility trucks including propane service trucks, has seen a strong move toward electronic meters. “As the younger crowd comes in to the propane market, we’re starting to see more technology updates, and more routing and scheduling programs, where they have to have electrical access in the trucks,” Terpstra said. “A lot of the guys, they used to have a route book and would go by and pop the dome tops and go from tank to tank. It’s become more sophisticated. They want to be more efficient. It’s interesting to me to see when I go to association meetings that I know the parents, the kids are now in the business, and we’re starting to see more of that. They’re more comfortable with the technology.”

Smith of Kurtz is seeing more demand for safety features such as caution lights, strobe lights, and back-up cameras. Automatic tire chains continue to be popular with Kurtz customers, but the chains are expensive, about $2500. The “sparkless” chains tend to wear down, so Smith recommends marketers remove the chains in the summer so they don’t get banged up. Danny McElroy, executive vice president/general manager of the Southwest Sales Center for White River Distributors (Dallas), is seeing increasing interest in pull-away protection devices. The added safety device prohibits the bobtail driver from driving away if the liquid hose is still connected to the customer’s tank.

Over the past few years, Smith has seen a move toward electronic meter systems and handhelds, but he has seen an acceleration of it lately. Lin’s is seeing more in-cab electronics that communicate with the office software so drivers don’t have to manually enter tickets at the end of the day. “We’ve seen quite a bit of growth in that area,” Swensen said. “We’re probably doing that on at least 50% of the trucks we’re building now. Three to four years ago, there was one here, one there, but it is a trend people are really starting to get on board with.”

More customers are looking for enhanced features on remote shut-offs, according to Steve Bloomstrand, sales and marketing manager for Rocket Supply (Roberts, Ill.). “For the most part, we’re going beyond just the single-function remote and selling the multi-function remotes, making deliveries more efficient for the operators on the trucks,” Bloomstrand said. They are using the remote to perform more truck functions from the house tank, such as the hose reel-out and remote meter readout. “They can hit a button and the hose reel will unwind as the operator walks to the house tank. They can also view the gallons being pumped if equipped with the remote meter readout option, while standing at the house tank.”

Liftgates, Decks

Rear deck and fender materials have broadened, as more dealers are trending toward either aluminum or stainless steel configurations, said Hudelson of Meeder.

“The biggest change I’ve run across [recently] is on liftgates on the back of trucks,” said Smith of Kurtz. He is handling more requests for an open-grate-design liftgate. The steel platforms eventually become uneven from heavy tanks slamming down on them. The open-grate design features heavier steel, and any dirt on it falls through, “which helps improve the fuel economy of the truck because you don’t have that big billboard slowing down the back of the truck when it’s in the up position,” Smith noted. “With the open-grate design, the air flows right through it. Think of it like a fire escape — that’s what the tailgate platform looks like. We’re selling more and more of them.”

Bloomstrand said Rocket Supply is receiving more interest in its co-polymer plastic deck for bobtails. Because the propane business is a winter business, the plastic deck works well because it doesn’t rust like metal and is lightweight, similar to aluminum. Bloomstrand noted the decks went through rigorous testing at the University of Illinois to verify that static electricity was not an issue with the poly deck.

Hydraulic Pumping Systems

White River Distributors is installing more hydraulic pumping systems this year. “They allow the drivetrains to last longer because you’re not engaging the PTO using the driveshaft,” McElroy explained. “It’s an auxiliary pumping system. You see it on a lot of transports, and now you’re seeing it on a lot of bobtails.” Some systems now include a handheld device that runs the PTO, throttle, and shut-down. For situations in which the battery begins to go low or the user misplaces the shut-off, White River installs a redundant system with a multi-function PTO on it.

Toolboxes

Kurtz Truck Equipment is selling high-end toolboxes with drawer units that go inside the cabinets on service trucks. “Ever see a mechanic’s toolbox? They’re putting something similar to that inside the cabinet where there are locks on the drawers and there are four or five drawers or more,” Smith said. “They can actually put partitions in them and keep small electronic parts or fittings and nuts and bolts where everything is organized and kept nice and neat.”

Training

Swensen of Lin’s is seeing more marketers conduct bobtail-related training with local fire departments. Lin’s provides a cutaway bobtail with the side cut out of it for training purposes. “We let customers use it. It didn’t get used a lot before, but we have had a lot more calls for people to use it to do their own training.”

Truck Rental

Utility 1 Source announced last July what it says is the first propane truck rental program. Users can rent propane bobtails by the month or for the winter. Terpstra of Utility 1 Source notes that the business is geared toward propane marketers who might use one bobtail as their main truck that runs year-round while only using its other trucks during the high volume winter season. “The idea behind this is to better control any operational truck-related expenses and enhance deliveries in peak time. Take the truck and turn it back in, and you’re not paying for the truck, you’re not paying insurance, you’re not paying to keep it running, all the things that are a large expense to the retailer.” The company started in Kansas City and plans to expand with additional locations in Denver and Phoenix, and Texas, Wisconsin, California, and Washington state.

More Good News: VW Funds

Last year, Volkswagen and the U.S. government reached an agreement in which VW would establish a $2.7-billion environmental mitigation trust fund to offset the estimated 59,000 tons of excess NOx emissions because of an emissions cheating scandal. For nearly six years, VW intentionally falsified the laboratory emissions testing, causing nearly 500,000 cars in the United States to emit 40 times the acceptable NOx standard, according to the National Propane Gas Association (NPGA). Propane-fueled vehicles are eligible for some of that funding, which is being provided to states to replace older, dirtier diesel vehicles with much cleaner models. “Propane has been successful in replacing diesel fleets,” NPGA wrote in an email alert on Feb. 9. “This settlement presents a great opportunity for propane marketers and other industry professionals to continue that success.”

NPGA has been engaged with the state propane gas associations and the Propane Education & Research Council (PERC) to develop propane industry outreach efforts for this settlement. This has included an informational “tool kit” that went to the state association executives in October, as well as a group discussion during the annual Leadership Summit in November. To help marketers take advantage of the opportunity to use the settlement funds for eligible propane vehicles, NPGA has developed letters that marketers can send to their state officials in charge of this funding.

Mouw of Roush CleanTech noted that his company is working with state propane gas associations to advocate that some of the state funding go toward propane school buses.

“Nothing has been finalized from a federal or state perspective, but we’re talking to representatives in every state as they put together their draft plan,” Mouw stated. “Based on our efforts, Michigan has tentatively earmarked $32 million of the $60 million for clean school buses, which would be propane or natural gas. We’re working with Blue Bird, its dealers, and state associations to make sure funding goes toward propane school buses.”

Although the propane trucking industry is seeing positive trends in terms of product development and adoption, warmer winters threaten to put a damper on the encouraging news. Pitts of Mississippi Tank said he has never seen a warmer winter than the current one in his part of the country and that he believes the Trump Administration will provide incentives for companies to spend money and pick up the economy.

“It was another average winter, and we really could use a colder-than-average winter,” said Swenson of Westmor. “They don’t spend a lot when they don’t run them a lot. If they do get a cold winter the next year, then they start spending money.” —Daryl Lubinsky

“It’s still a little slow. All of the truck builders I’ve talked to said it was a down year,” said Rob Vandemark, who runs the truck division for Industrial Propane Service Inc. (Byron, Mich.). Speaking to BPN in early February 2017, he added, “It’s still slow taking off this year. I think marketers are hanging on to see what happens with politics, the presidential election, and what [President Trump] is going to do. So we’re optimistic as far as sales.”

Roger Smith of Kurtz Truck Equipment (Marathon, N.Y.) agreed with Vandemark about the warm winter’s effect on truck sales. “The business environment this year is terrible because of the lack of winter last year,” he commented. “We started getting quiet in December, and now it’s real quiet. Business is off probably 35%. We’re shifting our mechanics around doing more repair work and less new builds. Probably the biggest trend right now is there is no trend because nobody is buying trucks.”

Because the mild weather has caused a decline in business for propane marketers, they are spending more to repair equipment that they probably shouldn’t, Smith noted. After a slow winter, many marketers can’t afford to buy new trucks, so patching up old ones instead is their only choice. “Slow winters bring a lot of headaches, not just for me but also the retail guys, because they’re running that older equipment longer and longer,” Smith added.

The news is not all bad, of course. Smith has seen an increase in crane truck orders, “like they’re going out of style.” Marketers are spending more money on hydraulic-operated crane trucks. In the past, Kurtz sold an average of about five hydraulic cranes per year, but the company received 10 orders in the first month of this year alone. The company’s customers have historically bought the less-expensive electric-over-hydraulic cranes.

“But now they’re shifting to the full-hydraulic cranes, because they’re realizing that electric-over-hydraulics just don’t hold up in our industry, and by going to the more expensive, more reliable, fully hydraulic crane, they will outlive two or three chassis,” Smith noted. Nathan Roberts of Fisk Tank Carrier (Columbus, Wisc.) is seeing an increase in boom truck sales. The reason? “I think people are changing to a one-man operation,” Roberts said. Marketers want installation and service to take place with one technician and one truck. The truck is becoming a warehouse. “People are setting them up and restocking them on a daily basis, keeping the jobs very efficient.” Customers of H&H Sales Co. (Huntertown, Ind.) have been purchasing more crane/service trucks with 14-ft-long bodies with 7000-lb capacity cranes to accommodate the transporting of 1000-gal. tanks with less overhang than on a 12-ft-long body, said H&H CEO John Hawkins.

More encouraging news: Ed Hoffman, president of Blossman Services (Ocean Springs, Miss.), said more propane marketers are expressing interest in running their fleets on autogas. “Our sales of the Ford F-Series trucks to the industry are way up,” Hoffman stated. “We see great adoption in tank-set trucks, service trucks, and bobtails. I’m excited about the adoption in the industry. The interest is there, which is great.”

Roush CleanTech (Livonia, Mich.) confirmed that its Ford F-750 bobtail orders are on the rise. Todd Mouw, vice president of sales and marketing for Roush CleanTech, heard in the early days of the F-750 bobtail development that few would buy the truck if it didn’t have air brakes. The product uses hydraulic brakes. “Now we’re seeing that trend go the other way. Propane companies are buying that truck for bobtails and cylinder exchange, which is good news,” Mouw stated, adding that the company has also seen an increase in demand for its medium-duty truck. Nestlé, which has ordered several hundred Roush CleanTech trucks for water-delivery applications, is one example. Mike Pitts, vice president of sales for Mississippi Tank (Hattiesburg, Miss.), pointed out that although his company is building more diesel-fueled trucks than propane models, “We would like as an industry to see that change. It depends on how well the technology holds up. More technology exists now. Three or four years ago, we had nothing that was truly a propane truck. Now we do have options out there.” Hawkins of H&H noted that “gasoline/propane power seems to be more active on new 2017-model-year Ford chassis than diesel engine power. We still have a few that will order diesel engines if they are in a multi-fuel-type business.”

Even though business is off overall, the products that are being sold continue to improve, becoming more durable and fuel efficient. The industry continues to see more customization of trucks to fit users’ specific needs, and use of the bobtail as more of a multi-use vehicle rather than simply a delivery vehicle.

Niche Trucks, Customization

Customers continue to be more involved in the design of the work trucks. They want the vehicles designed around the exact way they work.

“We’re a niche market, and now it’s starting to get to niche trucks that are inside that niche market,” said Roberts of Fisk Tank Carrier. Boom trucks are customized for the propane market, but inside that niche market, companies are ordering trucks pinpointed to another niche market. In this case, it is a truck with the primary task of delivering propane for temporary heat use. Propane marketers use these trucks to deliver tanks and propane to contractors for projects during the winter. Construction sites need heat in Roberts’ area of Wisconsin during a four- to five-month period.

Fisk recently sold a truck to a customer who needed it to be very precise for maneuverability in an extremely dense housing area of New England. “We’re seeing people are wanting what they want,” Roberts said, noting that efficiency with the right options is more valuable to customers now than low price. The truck is less of a commodity market item than it was even a couple years ago. “It’s more of a tailor-made-type situation.” Roberts adds that Fisk has seen great growth in the tank-carrier market segment. “We’ve literally had a backlog for a year and a half now.”

Vandemark of Industrial Propane Service noted his company’s Clear Vision Enclosure bobtail product (above) is a good example of customization. To provide greater visibility to the driver and to protect components from damage, the truck builders took all of the components—including the meter, hose reel, and piping—and “sucked it in and put it between the framerails of the chassis.”

The Bobtail: Different Uses

Propane marketers are looking for the bobtail to be available for various uses such as on-site cylinder filling, rather than just as a delivery vehicle, Vandemark noted. That particular use puts some strain on the normal delivery truck because the truck is built to pump 60 gpm, while cylinder filling only allows 6 gpm. “But they do it, and sometimes they plumb them a little differently so it’s less stress on the truck,” he noted. “It’s not a big thing, but we do see it and get asked about it.”

Customers of Westmor Industries (Morris, Minn.) have also asked for a bobtail that can fill cylinders. “We are looking at developing ideas for making the bobtail more of a multi-use vehicle,” said Milt Swenson, truck and trailer division sales manager for Westmor. “So we try to design systems that will allow the bobtail to do several different things rather than just fill domestic tanks or commercial tanks. We’re trying to make it more versatile.”

Marketers have told Westmor that they want products to make it easier to move propane back into the bobtail. The company is working on incorporating an evacuation-line system in the trucks to allow that. It will help improve efficiency and productivity for customers because they won’t have to use a different truck for the task. “And of course if you incorporate all that into one truck, it’s a lot less expensive than having to buy two or three vehicles to do the same jobs,” Swenson stated.

S2G Service

Kurtz’s Smith noted that in addition to the bobtail driver shortage that much of the industry is experiencing, a shortage of mechanics who can fix propane trucks is also a serious problem. When marketers who buy the Freightliner Custom Chassis Corp (FCCC) S2G propane-fueled bobtail need service on the vehicle, the Freightliner service people are not always as knowledgeable as they should be about the propane-fueled product, he added.

FCCC is taking steps to address that issue. Mike Stark, product manager, commercial chassis, for Freightliner, noted that S2G users often didn’t know whether to contact FCCC, Powertrain Integration, or CleanFUEL USA with service-related concerns. The entire service warranty process will now go directly through FCCC.

Dealer training is another area that FCCC is working to improve. The company has implemented a full-time training team with representatives from FCCC, Powertrain Integration, and CleanFUEL USA that will travel to train FCCC dealers on servicing the S2G and Thomas Built school buses.

“We want to be sure that 24/7, 365 days, you can call our call center and get an FCCC rep, not somebody who is maintaining phones but an actual rep who has technical expertise on the product,” Stark said. “We’re going to transition all the S2G product [questions] into our call center, which should alleviate a lot of questions and confusion for our customers.”

FCCC is also seeking to offer new options for the S2G, such as a new transmission and different power take-off (PTO), and wheelbase options. The company is also working on gearing the products to different vocations that typically use gasoline or diesel, and Stark noted FCCC is aiming toward offering new applications in the areas of beverage bodies and emergency vehicles. As an example, he noted that the company is in the early stages of working on switching from the S2G’s 2500 Allison transmission to an Allison 3000 series for an emergency vehicle application.

Stark also described the company’s increased emphasis on propane-specific sales training, including a 2016 national “road show.” In the fourth quarter of 2016, the company visited Freightliner dealers in Chicago, Charlotte, Boston, and Las Vegas, training the dealers on servicing the S2G. “At the end, we had dealers excited about the product, to take it on as a normal product within their portfolio and were excited to have it at their dealerships.”

Bigger (and Smaller) Tanks; Lightweighting

Lin’s Propane Trucks (Dighton, Mass.) has been building more bobtails with 5000-gal. barrels over the past couple of years. Scott Swensen, sales representative for Lin’s, noted that propane industry representatives in the past thought tandem-axle bobtails that can hold these larger tanks would “tear up driveways,” but that has not been the case.

“It’s kind of a change in mindset,” Swensen said. “A lot of places where there’s no trash pickup, they‘ve got dumpster guys going into these driveways all the time. They don’t have any issues. Most people are finding it works well for them. We’re moving a lot more of those.” He added that propane delivery drivers who used to load their 3499-gal. bobtails twice daily are now working more efficiently with the larger barrels.

Arch Hudelson, special projects director at Meeder Ransome (Fresno, Calif.), has noticed a trend for vessels with larger carrying capacity, “and the 3200-gallon WC vessels now greatly outnumber the small vessels in our production output. We are also viewing resurgence in requests for ‘jumbo’ bobtails with vessel sizes in the 4500-gallon to 5500-gallon range. These are typically designed as part of a three-axle straight truck or a single-axle ‘semi-trailer’ combination.” He is also seeing a trend of higher horsepower, “making these vehicles even more user-friendly in rugged terrain and heavily loaded situations.”

Smith at Kurtz is on the same page, noting that for the few trucks he is selling in the current challenging environment, “anything smaller than that 3499-gallon tank is pretty much obsolete.” His company is working on tandem bobtails with 4500- to 5500-gal. tanks, and even a couple of tri-axle 6000-gal. tanks. He explained that a tri-axle features two rear axles with an air-operated lift axle. “Tri-axle is a limited market. We have sold a few of them, but we’re seeing more and more tandems.” He added that in New York, the larger bobtail means higher sales and excise taxes. “That’s why people are hesitant to buy tandems, but more of them are saying that even with the ridiculous amount of taxes, it’s worth having.” In addition, with companies focusing more on driver productivity, they are looking to buy bigger trucks to keep the drivers on the road longer and delivering more gallons. He noted a disparity in wages among drivers in different areas of the country, which affects the choice of truck size. He heard that one company in Florida pays its drivers $14 per hour, while in his state of New York, he knows of a marketer paying $24. “It used to be that [the dealer] didn’t care what size truck they had because they would just run back, get another load, and go out and deliver. But if a company is delivering in an average 50- to 75-mile radius, if a driver is running back to get a second load, they’re losing an hour or two every time that truck goes empty.”

Pitts of Mississippi Tank is seeing few tanks below 2800 to 3000 gallons, and he pointed out the tanks get larger in the northern part of the country. The company is building 5000- to 6000-gal. tanks primarily for the major marketers’ northern state operations with large commercial accounts such as chicken or turkey houses or grain drying operations.

Several truck builders alluded to increasing truck sizes, but Swensen of Lin’s is also getting more requests for minis, and he mentioned a Ford F-550 with a 1200- or 1000-gal. barrel as an example. The truck can go almost anywhere, he noted, adding that weekend deliveries are a common use of the vehicles. “If you have an out-of-gas call, the tech can go there, do a leak check, and fill the tank at the same time.” Marketers are also using minis for cell tower accounts or rural camp areas. Lin’s previously built maybe one mini per year, but the company received more mini orders last year and has done about four or five so far this year.

Tim Schweppe, general manager of the propane division for Arrow Tank (Minneapolis), is seeing a focus on simplified troubleshooting and repair, “to get trucks pumping with all the new technology these days.” Marketers also continue to explore the option of using lightweight quenched and tempered (QT) vessels to further maximize bobtail payload. The increased payload comes with a significant cost upfront and with additional retest requirements, so companies must evaluate their application and decide whether the return on investment is sensible, Schweppe added. “Looking at single-axles, a 3499 vs. 3700 is more difficult to pencil out for a mere 171 gallons, but the tandem-axle vessels in excess of 5000 gallons make a guy scratch his head. Considering suitability for use on an equivalent chassis and the added capacity is what makes it more attractive. QT tanks are nothing new to Arrow as we manufacture everything onsite, including a state-of-the-art 110-ft PWHT (post weld heat treatment) oven needed to stress-relieve the material as part of the fabrication process.”

“Weight savings is a huge aspect of what everyone is doing,” said Roberts of Fisk. “You can see even Ford changing its body to aluminum. People are really trying to save weight. It’s cost savings for operational expenses for running the truck down the road, but they’re able to carry more payload, also. I think that’s becoming more the standard than it used to be.”

Driver Shortage: Creature Comforts

Swenson of Westmor addressed the driver shortage that is affecting the propane industry and others. “It’s almost like the days of a guy choosing a lifetime career delivering propane and refined fuels has come to an end. It’s hard to keep them when they have other opportunities.” He noted that propane truck builders are working on products with creature comforts to make truck driving a more attractive career option. He said his company’s Ergo-Load system features fill lines that are lower than those in conventional bobtails so drivers don’t have to lift the fill lines so high.

Meeder Ransome has fielded more requests from propane dealers for multi-point filling options when ordering new bobtails. Rather than choosing a rear-fill or a side-fill, they are asking for both. Hudelson added, “They explain the reason for such a configuration is flexibility in loading because they’re using multiple refueling sites within their operational area, and different fuel storage sites may favor opposite fill configurations.” Also, dealers are adding “driver-controlled” rear differential options for better control in wintry conditions.

Smart Bobtails, Troubleshooting

With all the new technology in the smart bobtails it builds, Arrow Tank is focusing on systematic design to simplify the troubleshooting and repair process. Schweppe noted that about 20 years ago, pumping issues were mechanical by nature and easily detected. “Fast forward to today, and the game has completely changed. We are using air and electronics to control a wide variety of components essential to the operation of the bobtail. The introduction of this technology has made the delivery process safer and more efficient, but [it] also has its challenges.”

Bobtails see their heaviest use during the harshest weather conditions, which Schweppe explained can be tough on some components. The components of today are robust and reliable, but they will only last so many cycles before they reach the end of their service life and fail. “Extremely cold temperatures expose the vulnerability of a component that is reaching the end of its service life. When the phone starts ringing off the hook, we know the temperature dropped around or below 0°F in this neck of the woods, and the troubleshooting process begins.”

It’s not a matter of if a component will fail, but when, Schweppe said. “Bobtails must be engineered to facilitate the troubleshooting process and procedures in place to handle that call from your customer. The bobtail operator reaches out to you as a lifeline expecting that you can make everything happy again. We need to make this happen quickly and with the least amount of pain and frustration due to an already compromised situation. When the call comes in, we picture ourselves in their shoes walking around the truck inspecting each element, and the design of our bobtails is systematic to make this easier.”

Schweppe added that Arrow has worked with its vendors to change the designs of products to be more “plug and play”-friendly to help facilitate repairs and the troubleshooting process. “Such changes come with an extra cost upfront, but it is invaluable when a compromised situation arises.”

Electronics, New Gadgets, Safety Features

Wayne Terpstra of Utility 1 Source (Kansas City, Mo.), which builds utility trucks including propane service trucks, has seen a strong move toward electronic meters. “As the younger crowd comes in to the propane market, we’re starting to see more technology updates, and more routing and scheduling programs, where they have to have electrical access in the trucks,” Terpstra said. “A lot of the guys, they used to have a route book and would go by and pop the dome tops and go from tank to tank. It’s become more sophisticated. They want to be more efficient. It’s interesting to me to see when I go to association meetings that I know the parents, the kids are now in the business, and we’re starting to see more of that. They’re more comfortable with the technology.”

Smith of Kurtz is seeing more demand for safety features such as caution lights, strobe lights, and back-up cameras. Automatic tire chains continue to be popular with Kurtz customers, but the chains are expensive, about $2500. The “sparkless” chains tend to wear down, so Smith recommends marketers remove the chains in the summer so they don’t get banged up. Danny McElroy, executive vice president/general manager of the Southwest Sales Center for White River Distributors (Dallas), is seeing increasing interest in pull-away protection devices. The added safety device prohibits the bobtail driver from driving away if the liquid hose is still connected to the customer’s tank.

Over the past few years, Smith has seen a move toward electronic meter systems and handhelds, but he has seen an acceleration of it lately. Lin’s is seeing more in-cab electronics that communicate with the office software so drivers don’t have to manually enter tickets at the end of the day. “We’ve seen quite a bit of growth in that area,” Swensen said. “We’re probably doing that on at least 50% of the trucks we’re building now. Three to four years ago, there was one here, one there, but it is a trend people are really starting to get on board with.”

More customers are looking for enhanced features on remote shut-offs, according to Steve Bloomstrand, sales and marketing manager for Rocket Supply (Roberts, Ill.). “For the most part, we’re going beyond just the single-function remote and selling the multi-function remotes, making deliveries more efficient for the operators on the trucks,” Bloomstrand said. They are using the remote to perform more truck functions from the house tank, such as the hose reel-out and remote meter readout. “They can hit a button and the hose reel will unwind as the operator walks to the house tank. They can also view the gallons being pumped if equipped with the remote meter readout option, while standing at the house tank.”

Liftgates, Decks

Rear deck and fender materials have broadened, as more dealers are trending toward either aluminum or stainless steel configurations, said Hudelson of Meeder.

“The biggest change I’ve run across [recently] is on liftgates on the back of trucks,” said Smith of Kurtz. He is handling more requests for an open-grate-design liftgate. The steel platforms eventually become uneven from heavy tanks slamming down on them. The open-grate design features heavier steel, and any dirt on it falls through, “which helps improve the fuel economy of the truck because you don’t have that big billboard slowing down the back of the truck when it’s in the up position,” Smith noted. “With the open-grate design, the air flows right through it. Think of it like a fire escape — that’s what the tailgate platform looks like. We’re selling more and more of them.”

Bloomstrand said Rocket Supply is receiving more interest in its co-polymer plastic deck for bobtails. Because the propane business is a winter business, the plastic deck works well because it doesn’t rust like metal and is lightweight, similar to aluminum. Bloomstrand noted the decks went through rigorous testing at the University of Illinois to verify that static electricity was not an issue with the poly deck.

Hydraulic Pumping Systems

White River Distributors is installing more hydraulic pumping systems this year. “They allow the drivetrains to last longer because you’re not engaging the PTO using the driveshaft,” McElroy explained. “It’s an auxiliary pumping system. You see it on a lot of transports, and now you’re seeing it on a lot of bobtails.” Some systems now include a handheld device that runs the PTO, throttle, and shut-down. For situations in which the battery begins to go low or the user misplaces the shut-off, White River installs a redundant system with a multi-function PTO on it.

Toolboxes

Kurtz Truck Equipment is selling high-end toolboxes with drawer units that go inside the cabinets on service trucks. “Ever see a mechanic’s toolbox? They’re putting something similar to that inside the cabinet where there are locks on the drawers and there are four or five drawers or more,” Smith said. “They can actually put partitions in them and keep small electronic parts or fittings and nuts and bolts where everything is organized and kept nice and neat.”

Training

Swensen of Lin’s is seeing more marketers conduct bobtail-related training with local fire departments. Lin’s provides a cutaway bobtail with the side cut out of it for training purposes. “We let customers use it. It didn’t get used a lot before, but we have had a lot more calls for people to use it to do their own training.”

Truck Rental

Utility 1 Source announced last July what it says is the first propane truck rental program. Users can rent propane bobtails by the month or for the winter. Terpstra of Utility 1 Source notes that the business is geared toward propane marketers who might use one bobtail as their main truck that runs year-round while only using its other trucks during the high volume winter season. “The idea behind this is to better control any operational truck-related expenses and enhance deliveries in peak time. Take the truck and turn it back in, and you’re not paying for the truck, you’re not paying insurance, you’re not paying to keep it running, all the things that are a large expense to the retailer.” The company started in Kansas City and plans to expand with additional locations in Denver and Phoenix, and Texas, Wisconsin, California, and Washington state.

More Good News: VW Funds

Last year, Volkswagen and the U.S. government reached an agreement in which VW would establish a $2.7-billion environmental mitigation trust fund to offset the estimated 59,000 tons of excess NOx emissions because of an emissions cheating scandal. For nearly six years, VW intentionally falsified the laboratory emissions testing, causing nearly 500,000 cars in the United States to emit 40 times the acceptable NOx standard, according to the National Propane Gas Association (NPGA). Propane-fueled vehicles are eligible for some of that funding, which is being provided to states to replace older, dirtier diesel vehicles with much cleaner models. “Propane has been successful in replacing diesel fleets,” NPGA wrote in an email alert on Feb. 9. “This settlement presents a great opportunity for propane marketers and other industry professionals to continue that success.”

NPGA has been engaged with the state propane gas associations and the Propane Education & Research Council (PERC) to develop propane industry outreach efforts for this settlement. This has included an informational “tool kit” that went to the state association executives in October, as well as a group discussion during the annual Leadership Summit in November. To help marketers take advantage of the opportunity to use the settlement funds for eligible propane vehicles, NPGA has developed letters that marketers can send to their state officials in charge of this funding.

Mouw of Roush CleanTech noted that his company is working with state propane gas associations to advocate that some of the state funding go toward propane school buses.

“Nothing has been finalized from a federal or state perspective, but we’re talking to representatives in every state as they put together their draft plan,” Mouw stated. “Based on our efforts, Michigan has tentatively earmarked $32 million of the $60 million for clean school buses, which would be propane or natural gas. We’re working with Blue Bird, its dealers, and state associations to make sure funding goes toward propane school buses.”

Although the propane trucking industry is seeing positive trends in terms of product development and adoption, warmer winters threaten to put a damper on the encouraging news. Pitts of Mississippi Tank said he has never seen a warmer winter than the current one in his part of the country and that he believes the Trump Administration will provide incentives for companies to spend money and pick up the economy.

“It was another average winter, and we really could use a colder-than-average winter,” said Swenson of Westmor. “They don’t spend a lot when they don’t run them a lot. If they do get a cold winter the next year, then they start spending money.” —Daryl Lubinsky